Contents

Did you know that over 40% of industrial equipment failures are caused by motor-related issues? Many still believe that “a powerful motor doesn’t need protection” — a dangerously common misconception. In this article on the Tech4Ultra Electrical website, you’ll discover the essentials of motor protection, explore key motor protection devices, and learn how to prevent critical motor faults. If you want to reduce downtime and boost operational efficiency, you’re in the right place.

Understanding Motor Faults

I used to think motor issues were easy to spot — until I experienced an unexpected shutdown that nearly halted an entire production line. That moment changed how I looked at motor protection. Most people focus on external signs, but understanding the different types of motor faults is key to preventing costly failures.

Internal Faults

Let’s start from the inside — literally. Internal motor faults are the ones I’ve learned to fear the most because they’re often invisible until it’s too late.

- Winding failures: One of the most common issues. Over time, insulation degrades, especially in high-temperature environments. I once had to replace a motor simply because the insulation cracked during peak summer operations.

- Overheating: Motors can run hot, but excessive heat kills. Without proper motor protection devices, thermal damage sneaks up fast — especially if the motor’s cooling system isn’t maintained.

- Bearing damage: If you hear grinding or humming, it might already be too late. Bearing wear can escalate quickly, leading to unbalance and rotor misalignment.

- Earth leakage: Small leakages can become dangerous over time, leading to safety hazards and motor trips.

External Faults

Even when your motor is healthy internally, the environment can still cause chaos. External faults account for a surprising number of failures in my experience.

- Voltage unbalance: An unbalanced voltage stresses the motor, increasing current in one phase and reducing efficiency.

- Phase failure: Also known as single phasing — I’ve seen motors burn out in minutes when one phase dropped unexpectedly.

- Under-voltage conditions: Insufficient voltage may seem harmless but causes the motor to draw more current, which leads to heating.

- Power supply issues: Frequent voltage sags or spikes can damage motor controls and reduce lifespan significantly.

Hidden and Intermittent Faults

Now this is where most overlook — the hidden culprits. These faults are rarely covered in guides, but from experience, they’re just as dangerous.

- Vibration-related faults: I once ignored minor vibrations from a floor-mounted fan motor — it ended up loosening internal components over months.

- Temporary overloads due to duty cycle changes: A change in load profile or machine usage pattern can push motors beyond their design limits without triggering alarms immediately.

- Environmental stress (humidity, dust): Motors in dusty, humid environments are at high risk. A simple dust layer can act like an insulator and cause overheating.

Understanding these layers of motor faults is the first step toward choosing the right motor protection devices — and ultimately, keeping your systems running longer and safer.

Read Also: Low Voltage Switchgear: Types, Components, and Uses

Categories of Motor Protection

After a few hard lessons (and a couple of burned-out motors), I realized that choosing the right motor protection devices isn’t just about picking the most expensive or advanced ones — it’s about understanding which type of motor protection actually matches the risks you face. Each category plays a specific role, and missing even one could cost you hours of downtime or worse.

Overcurrent and Overload Protection

Every time a motor is forced to handle more load than it should, you risk overheating and premature failure. That’s where overload protection kicks in. I’ve used thermal overload relays that trip when the current exceeds safe limits — a lifesaver during production peaks.

Short-Circuit Protection

Short circuits are like sudden lightning strikes — fast and brutal. Devices like circuit breakers and fuses are your first line of defense. Once, a faulty terminal connection caused a massive arc, but thanks to the installed breaker, the damage was isolated instantly.

Ground Fault Protection

Undetected ground faults are silent threats. I remember a case where a slight insulation failure led to leakage current that almost went unnoticed. Devices like ground fault relays not only detect this but isolate it quickly, preventing larger motor faults.

Overtemperature and Thermal Protection

Overheating can be gradual, but it’s deadly. Modern sensors — including embedded RTDs and thermistors — can monitor winding temperature in real-time. I learned to never ignore rising heat — it’s often the last warning before failure.

Phase Sequence and Phase Loss Protection

If you’ve ever wired a three-phase motor backward (guilty as charged), you’ll know why this matters. Incorrect phase sequence can reverse motor rotation, while a missing phase can kill efficiency or even stall the motor.

Speed and Torque Monitoring

This one’s a game-changer for industrial sites. In applications like conveyors or extruders, monitoring speed and torque can catch mechanical jams or load changes before they damage the motor. I once spotted a gearbox issue just because the torque readings jumped out of range.

When you combine these motor protection methods, your system becomes far more resilient — and trust me, it’s cheaper to prevent motor faults than to fix them after a failure.

Types of Motor Protection Devices

When I first got into motor maintenance, I assumed all motor protection devices were created equal — plug and play, right? Not even close. Each type has its own niche, and choosing the wrong one can either leave your motor vulnerable or drive up costs unnecessarily. Here’s what I’ve learned from experience (and a few mistakes) about the most common protection devices out there.

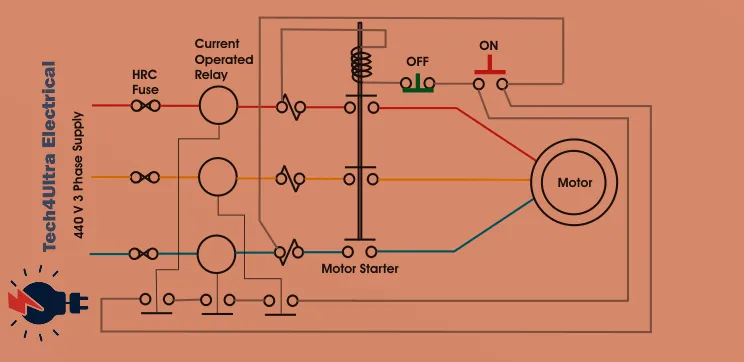

Fuses

Ah yes, the humble fuse. I started out using HRC fuses (High Rupturing Capacity), thinking they were enough. They’re great for short-circuit protection in small motors — fast, affordable, and simple.

- Pros: Inexpensive, quick to respond to faults, easy to replace.

- Cons: No reset feature, single-use, and no thermal overload protection — a major drawback for continuous-duty applications.

Circuit Breakers

Once I started handling larger setups, I moved to MPCBs (Motor Protection Circuit Breakers) and MCCBs (Molded Case Circuit Breakers). These not only trip on short circuits but also handle overloads well.

The trick is understanding instantaneous trip (for immediate short-circuit protection) versus inverse-time trip (where the trip time depends on the magnitude of the fault current). The latter has saved my motors from slow-burn overloads more times than I can count.

Thermal Overload Relays

Here’s a classic: bimetallic thermal relays. They use two metals with different expansion rates to trip when the motor gets too hot. Simple, effective, but with limited precision. I’ve upgraded to electronic thermal relays in recent years for tighter accuracy — no more guessing if the trip was legit or just over-sensitive.

Electronic Overload Relays

If you’re into smart factories or predictive maintenance, this is where you level up. These relays offer real-time diagnostics, communication capabilities (via Modbus or Ethernet), and adjustable trip curves. I once diagnosed a near-failure in a remote motor station — all thanks to one of these relays sending me an alert via SCADA.

Differential Protection Relays

This one took me a while to grasp. The idea is simple: if the current going into the motor isn’t the same as the current coming out, something’s wrong internally. Differential relays are essential for large LV and MV motors, especially those driving critical equipment. We installed these in a wastewater treatment plant, and they’ve caught internal winding faults early, avoiding major outages.

Reverse Rotation Protection

Ever wired a motor and watched it spin the wrong way? It’s not fun — belts slip, pumps cavitate, and time is lost. Phase detection relays help avoid this. They detect incorrect phase sequences and cut power before damage happens. We use them on all conveyor systems where rotation direction really matters — a single wiring error without protection can ruin bearings in hours.

In short, selecting the right motor protection devices isn’t just about checking boxes. It’s about matching the device to the application — and knowing what could go wrong before it actually does. Trust me, a few hundred bucks spent upfront beats thousands lost in repairs or downtime from unexpected motor faults.

Advanced Motor Protection Technologies

Back when I started, motor protection was all about relays and breakers. Fast forward a few years, and now I’m working with systems that talk back, diagnose themselves, and even send alerts to my phone. Welcome to the future of motor protection.

IoT-enabled Protection Systems

One of the biggest breakthroughs I’ve seen is the rise of IoT-based motor protection devices. These systems monitor everything — temperature, current, vibration — and send real-time data to the cloud. We use them in critical pumps and compressors, and they’ve helped us catch issues long before they became actual motor faults.

Predictive Maintenance Using Sensors

Gone are the days of reactive maintenance. With embedded sensors in motors and connected systems, we now track trends like winding temperature drift or slight increases in vibration. I once avoided a complete motor failure simply because the sensor data flagged an early sign of bearing wear. That’s what predictive maintenance is all about — solving problems before they exist.

Integration with SCADA and Automation Systems

SCADA integration was a game-changer for us. Now I can view the status of dozens of motors from a single control room. These modern systems pull in data from motor protection devices, automate shutdowns if certain thresholds are crossed, and give us detailed logs to troubleshoot later. It’s not just about protection anymore — it’s about intelligence.

Advanced motor protection isn’t just for big factories — it’s quickly becoming the new standard. If you’re serious about minimizing downtime and maximizing motor lifespan, it’s time to embrace these tools.

NEC Guidelines for Motor Protection Selection

When I first had to size protection for a motor according to the NEC, I was overwhelmed. The codebook felt like a maze. But over time — and a few consultations with seasoned electricians — I learned to break it down step by step. These guidelines make a real difference in ensuring your motor protection devices are not just effective, but compliant too.

Full-load Current Calculation

Everything starts here. The NEC provides standard full-load current values in Table 430.250 based on motor horsepower and voltage. You’ll use these values — not the motor’s nameplate — to size breakers, overloads, and conductors. I’ve seen many missteps from relying solely on nameplate data, especially with older motors.

Protection Rating Based on Service Factor

This part surprised me. Motors with a service factor of 1.15 or higher can use slightly higher overload settings, giving you more flexibility. It’s all in NEC 430.32 — and knowing this detail saved me from nuisance tripping in a high-load HVAC application.

Branch Circuit Protection Requirements

The branch circuit — from the panel to the motor starter — must be protected from short circuits and ground faults. According to NEC 430.52, you can size the protection device (like an MCCB or fuse) up to 250% of the full-load current for time-delay fuses. It’s a balance: too low, and you get nuisance trips; too high, and you risk under-protection.

Conductor Sizing per NEC Tables

NEC 430.22 and Chapter 9 help determine conductor size. You’ll size the wire at 125% of the motor’s full-load current. In one project, switching from #12 AWG to #10 based on this rule stopped the insulation issues we were having in a 3-phase motor line.

Motor Control Circuit Considerations

Control circuits are often overlooked. NEC 430.72 covers them in detail — making sure the control wiring itself is protected. This includes fuse or breaker protection and proper isolation. I’ve had to redo panels that lacked this — it’s critical for both safety and maintenance.

Following the NEC isn’t about red tape — it’s about reliable, safe motor protection. Once you get familiar with these steps, choosing and sizing motor protection devices becomes second nature — and your motors stay compliant and protected against the most common motor faults.

How to Select the Right Protection Device

Picking the right motor protection setup isn’t just about following code — it’s about knowing your motor, your application, and how much downtime you can afford. I’ve had to make these decisions dozens of times, and trust me, it’s rarely one-size-fits-all. Here’s what I’ve learned through trial, error, and a few near-misses.

Based on Motor Type

- Induction motors: These are the most common. Standard overload and short-circuit protection is usually enough, unless you’re dealing with high-inertia loads where thermal buildup is a concern.

- Synchronous motors: These need more care. I always add protection for rotor field failure and ensure differential relays are used in larger units — especially in industrial drives.

- DC motors: These require protection against armature and field faults. I usually use relays that detect field loss, reverse polarity, and overloads — skipping any one of those has cost me hours of troubleshooting in the past.

Based on Size

Motor size really changes the game. A fractional HP motor in a residential fan doesn’t need what a 150 HP pump motor demands.

- Small motors (<1 HP): Basic thermal overloads or fuses usually suffice. Cost and simplicity win here.

- Medium motors (1–100 HP): I go for electronic overload relays and MCCBs. You want good fault discrimination and reset capabilities.

- Large motors (>100 HP): These need comprehensive systems — short-circuit, overload, ground fault, and often differential and temperature monitoring. We used a full relay panel for a 200 HP chiller pump and caught a ground fault before it escalated.

Based on Application

Different applications have very different profiles. I learned this the hard way after using the same settings for a fan and a conveyor — the conveyor kept tripping under load.

- Fans: Typically low torque. Protection is mostly against overcurrent and overheating.

- Compressors: These can have high starting currents and pressure-related stalls. I always use time-delay relays to prevent nuisance trips.

- Conveyors: Highly variable load. Torque and speed monitoring become crucial here, along with protection against jamming.

Cost vs Reliability Trade-offs

There’s always a balance between budget and protection depth. Early in my career, I skimped on monitoring for a remote pump site to save a few hundred dollars — ended up paying thousands when the motor failed. Since then, I prioritize reliability where downtime is costly.

Manufacturer Guidelines

Always — and I mean always — check the motor manufacturer’s specs. I once missed a hidden requirement for thermistor integration in a VFD-rated motor, which led to overheating issues. These documents are gold mines for exact settings and compatible motor protection devices.

Choosing the right motor protection isn’t about guesswork. It’s about understanding the motor’s role, its risks, and how much margin for error you really have. The more precise your selection, the fewer motor faults you’ll face — and the more peace of mind you’ll earn.

Common Mistakes in Motor Protection Design

If I had a dollar for every time I’ve seen a motor fail because of poor protection design, I’d have retired early. The truth is, even experienced professionals can slip up. The most dangerous part? These mistakes often go unnoticed — until something burns out. Let’s walk through the common traps I’ve encountered over the years.

Overprotecting or Underprotecting Motors

I once worked with a site that had every relay imaginable on a 2 HP fan motor — completely overengineered. The result? Nuisance trips and frustrated operators. On the flip side, I’ve seen massive motors running with basic thermal relays, leaving them vulnerable to serious motor faults. It’s all about balance. Match the motor protection devices to the actual risk — not assumptions.

Ignoring Environmental Conditions

This is the silent killer. Heat, humidity, dust, and vibration can all undermine motor health. I’ve seen motors in humid basements fail because their protection didn’t include moisture or thermal sensors. Always factor in where the motor operates — not just what it powers.

Wrong Fuse/Circuit Breaker Sizing

This one’s a classic. Using nameplate current instead of NEC full-load current data leads to either oversized breakers (which won’t trip) or undersized ones (which trip too often). I’ve had to redo entire panels because of this mistake. Always consult NEC 430 tables and the motor specs before locking in your design.

Getting motor protection right isn’t about throwing in more devices — it’s about smart, tailored decisions. These mistakes may seem minor, but they’re often the first step toward downtime, damage, and expensive repairs.

Watch Also: What Is an Electrical Grid System? Structure, Components, and Advantages Explained

Real-World Examples and Case Studies

Over the years, I’ve learned that nothing teaches you better than seeing motor protection devices in action — or watching the consequences when they’re missing. Here are a few cases that shaped how I approach motor fault prevention today.

Case 1: Industrial HVAC System

We were running a large HVAC control system in a commercial high-rise. The blower motor, rated at 75 HP, kept tripping unexpectedly during peak summer load. After investigating, we found the thermal overload relay was set too conservatively. By adjusting the trip curve and replacing the bimetallic unit with an electronic overload relay, we eliminated false trips and ensured proper motor protection under varying conditions.

Case 2: Water Pumping Station

At a remote water pumping site, a 100 HP motor failed without warning. The root cause? A slow-developing internal ground fault. The protection system included only basic overload and short-circuit protection — no ground fault detection. After the incident, we added differential and ground fault relays. Since then, the system has flagged and isolated three minor faults before they became catastrophic.

Case 3: Motor Failure Due to Undervoltage

One project stands out — a conveyor motor in a manufacturing plant that failed due to undervoltage. The voltage dipped repeatedly during peak load, causing the motor to draw excess current and overheat. Unfortunately, the installed protection didn’t include undervoltage detection. We learned the hard way. Now, undervoltage relays are part of every panel we design for motors above 5 HP — especially in facilities with unstable grid conditions.

Each of these cases reinforced a lesson: there’s no such thing as a “minor” motor fault when protection is inadequate. Smart motor protection devices don’t just react — they prevent the damage in the first place.

Conclusion

After working with motors for years, I’ve come to see motor protection as more than just a technical requirement — it’s an investment in reliability, safety, and peace of mind. From understanding different motor faults to selecting the right motor protection devices, every choice you make has a ripple effect across your entire operation.

The long-term benefits? Fewer breakdowns, lower repair costs, higher uptime, and above all, safer equipment for your team. I’ve seen companies save thousands simply by upgrading protection systems that were ten years out of date.

One final tip: always align your protection strategy with NEC guidelines and your motor’s manufacturer specifications. These aren’t just regulations — they’re field-tested frameworks designed to help you get the most out of your system.

FAQs

What are the different types of motor protection?

Motor protection can be categorized into several types: overcurrent protection, overload protection, short-circuit protection, ground fault protection, overtemperature protection, phase loss and phase sequence protection, and advanced options like torque and speed monitoring. Each targets specific motor faults to prevent damage and downtime.

What are the protective devices for motors?

Common motor protection devices include fuses, circuit breakers (MPCB, MCCB), thermal and electronic overload relays, differential protection relays, undervoltage and overvoltage relays, and phase failure detectors. The selection depends on motor type, size, and application.

What are motor faults?

Motor faults refer to abnormal conditions that affect motor operation. These include internal issues like winding failure, overheating, and bearing wear, as well as external faults like phase loss, voltage imbalance, and power supply disturbances. Undetected faults can cause severe equipment failure.

What type of motor protection protects against ground faults?

Ground fault protection is achieved using ground fault relays or differential protection relays. These devices detect current leakage to ground — often an early sign of insulation breakdown or internal short — and disconnect the motor before serious damage occurs.

1 thought on “What is a Megger? Working Principle and Applications”