Contents

Ever confused an Electric Generator with an Alternator or a Dynamo? You’re not alone. Many people assume these devices are interchangeable, but each operates differently and serves a unique purpose. Without understanding their distinctions—and how they rely on Electromagnetic induction to generate EMF (Electromotive Force)—you could end up choosing the wrong one for your needs. This article on the Tech4Ultra Electrical website will break down the differences in simple terms, so you can make informed decisions and truly understand how these power sources work.

Fundamental Principle: Electromagnetic Induction

The first time I learned about Electromagnetic induction, it felt like discovering a magic trick—only it was backed by science. At its core is Faraday’s Law, which says that when a magnetic field moves through a conductor, or when the conductor moves through a magnetic field, it creates EMF—that is, Electromotive Force. Simply put, motion and magnetism combine to generate electricity. That’s the basic idea behind every Electric Generator, Alternator, and Dynamo.

To visualize it, imagine waving a wire through the air. Now imagine that air is filled with invisible magnetic lines. As the wire cuts through them, it’s like stirring through invisible currents—the electrons in the wire start moving. That’s current.

I once did a basic experiment in class: wrapped a copper wire around a nail, connected it to a galvanometer, and moved a magnet in and out. The needle jumped. That was Electromagnetic induction in action. It’s a simple idea, but incredibly powerful—one that powers cities, keeps your fridge running, and even lets your car charge its battery as it drives.

Read Also: Transformer Efficiency Explained: Calculation, Losses, and Optimization Strategies

Understanding EMF and Fleming’s Right Hand Rule

If you’ve ever wondered what exactly EMF is, it’s not as mysterious as it sounds. It stands for Electromotive Force, and it’s basically the voltage produced by Electromagnetic induction. When a conductor cuts across magnetic field lines, this interaction causes electrons to move—producing current. That movement of electrons is driven by EMF.

To predict the direction of this current, I always turn to Fleming’s Right Hand Rule. It’s incredibly useful—and honestly, kind of fun to do. Here’s how it works, step-by-step:

- Stretch out your right hand.

- Point your thumb in the direction the conductor is moving (motion).

- Point your index finger in the direction of the magnetic field (from North to South).

- Your middle finger, held at a right angle to the other two, will point in the direction of the induced current (EMF).

Imagine holding a wire and moving it downward through a horizontal magnetic field—your thumb points down, your index finger points sideways, and your middle finger shoots forward. That’s your current. Simple, right?

Single Loop Generator Explained with Animation Reference

Picture this: a single wire loop rotating between two magnetic poles—this simple setup is the heart of a Single Loop Electric Generator. I remember the first time I saw an animation of it, and suddenly everything clicked. As the loop spins inside a magnetic field, different parts of the wire move through the field in opposite directions. That motion, thanks to Electromagnetic induction, creates EMF.

Here’s the cool part—because the loop rotates, the direction of the induced current changes every half-turn. That’s how Alternating EMF is generated. You get positive current in one half of the turn, and negative in the other. The result? A smooth, wavy current that goes up and down—this is called a sinusoidal waveform.

If you could watch this in animation (and you should!), you’d see the voltage rise and fall like ocean waves. The peaks and troughs of this wave represent the alternating flow of current. And yes, this is exactly how most of the electricity in your home is produced—by spinning loops of wire in magnetic fields.

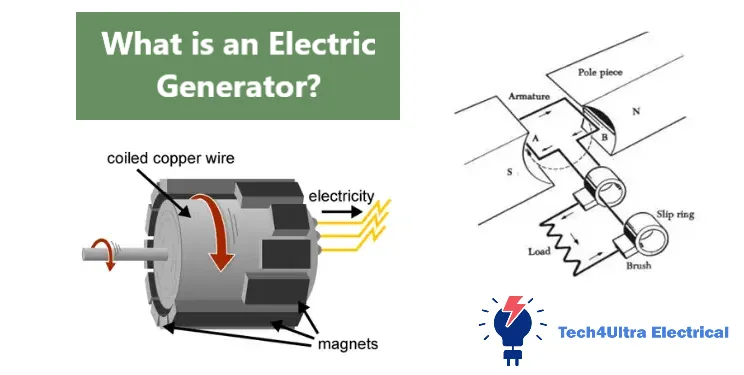

Components of a Generator

When I first opened up a small Electric Generator, I was surprised at how organized everything was. Each part had a clear job—no wasted space. Let’s break it down:

- Rotor: This is the rotating part. It’s connected to a shaft that spins—usually powered by wind, water, or a motor. Its motion is what cuts the magnetic field lines to produce EMF.

- Stator: The stator is the stationary part that houses the coils of wire. It’s where the electricity is induced thanks to the spinning rotor inside its magnetic field.

- Armature: This is the actual coil of wire inside the stator that collects the induced current. In simple generators, it’s part of the rotor itself.

- Brushes: These are soft carbon pieces that maintain contact with moving parts like the commutator or slip rings, allowing the current to flow out to external circuits without friction sparks.

- Commutator (in DC generators) or Slip Rings (in AC alternators): These manage how current flows—either switching direction (commutator) or maintaining continuous rotation without switching polarity (slip rings).

What’s amazing is how each of these parts depends on the other. Without the rotor’s movement, there’s no induction. Without brushes and slip rings, there’s no way to extract that electricity. It’s a seamless system.

Types of Electric Generators

There are two main types of Electric Generators—each with its own setup and purpose. The first time I opened an Alternator, I was shocked (not literally!) by how it cleverly produced AC power. Let’s break them down.

AC Generator (Alternator)

In an AC Generator, also known as an Alternator, the coil rotates inside a magnetic field. As it spins, the direction of current keeps reversing—producing Alternating Current. The key to this is the slip rings. These metal rings rotate with the coil and maintain a smooth connection with the brushes, allowing the current to alternate naturally without interference.

DC Generator

DC Generators also use a rotating coil, but instead of slip rings, they use a commutator. The commutator’s job is to flip the connection every half-turn, ensuring the output current always flows in the same direction. This is called current rectification. The brushes touch the commutator, collecting the current and sending it out as steady Direct Current.

AC vs. DC Generator Comparison

| Feature | AC Generator (Alternator) | DC Generator |

|---|---|---|

| Output Current | Alternating Current (AC) | Direct Current (DC) |

| Main Component for Output Control | Slip Rings | Commutator |

| Current Direction | Reverses periodically | Stays constant |

| Usage | Power grids, household electricity | Batteries, small DC devices |

| Maintenance | Less frequent | Brush and commutator wear faster |

Each has its place—Alternators are great for large-scale, consistent power, while DC Generators shine in systems needing steady, one-way flow.

Energy Conversion in Practice

Every time you switch on a light or run your washing machine, you’re seeing Electromagnetic induction at work—quietly converting mechanical energy into electricity through an Electric Generator. In homes, this process usually starts at a power plant where massive turbines—driven by steam, water, or wind—spin a rotor inside a stator. That motion creates EMF, sending AC electricity through the grid.

In industrial settings, it’s much the same, only scaled up. Generators powered by internal combustion engines or gas turbines provide backup or continuous power for factories, data centers, and remote installations. These generators rely on Alternators to deliver stable, high-voltage electricity across complex systems.

But no system is perfectly efficient. Energy is always lost—mostly as heat due to friction in moving parts or resistance in wires. That’s why cooling systems and efficient brush designs are critical. Even the best generators rarely exceed 95% efficiency.

Mechanical energy sources vary—from water wheels in hydroelectric dams to diesel engines in mobile generators. The better the energy source, the more consistent and efficient your electricity production.

Watch Also: Star Delta Starter: Comprehensive Guide to Working, Circuits, and Applications

Modern Generator Technologies

Over the years, I’ve used everything from loud diesel machines to sleek, silent portable generators. These compact units are lifesavers during outages and camping trips. They rely on small internal combustion engines to spin a rotor and produce EMF using Electromagnetic induction—just like their bigger cousins.

But today’s energy solutions are getting smarter and cleaner. Wind-powered generators and hydroelectric turbines are changing the game. Both work by turning natural motion—air or water—into rotational force that drives an Electric Generator. No fuel, no emissions—just pure, renewable energy. These setups often use Alternators to produce grid-ready AC power.

One of the coolest advances I’ve come across is the Permanent Magnet Generator. Instead of using electromagnets powered by a separate current, they rely on built-in magnets to create a constant magnetic field. This makes them highly efficient, reliable, and perfect for wind turbines and off-grid systems.

Modern generators aren’t just about backup—they’re shaping the future of sustainable power, one magnetic field at a time.

Conclusion

Now that you’ve explored the world of Electric Generators, you’ve seen how they work—from the fundamentals of Electromagnetic induction and EMF to the roles of components like rotors, stators, and commutators. You’ve learned the difference between Alternators and DC Generators, and how energy is converted in homes, industries, and renewable systems.

Understanding these basic principles isn’t just for engineers. It empowers you to make smarter decisions—whether you’re choosing a backup generator, troubleshooting power issues, or simply appreciating the science that keeps your lights on. And remember, at the heart of every generator is a simple idea: motion plus magnetism equals electricity.

Common Misconceptions and FAQs

Is EMF the same as voltage?

Not exactly. EMF (Electromotive Force) is the potential generated by Electromagnetic induction, while voltage is the potential difference measured across a load. EMF is the cause; voltage is the effect.

Can a generator run forever?

I used to think so—until I realized even the best Electric Generator needs fuel, maintenance, and rest. Wear on brushes, bearings, and heat losses mean no generator can run endlessly without intervention.

What’s the difference between a motor and a generator?

Simple: a motor converts electrical energy into mechanical movement, while a generator does the reverse—turns motion into electricity using EMF and Electromagnetic induction. In fact, many devices can be used as both with minor tweaks!

What is the basic principle of electric generator?

The basic principle behind an Electric Generator is Electromagnetic induction. When a conductor moves through a magnetic field, or the magnetic field around it changes, it induces an EMF—which causes current to flow. This principle is the foundation of how we convert mechanical energy into electrical energy.

What is the working principle law of generator?

Generators operate according to Faraday’s Law of Electromagnetic Induction. This law states that the induced EMF in a closed loop is proportional to the rate of change of the magnetic flux through the loop. Simply put: move a wire through a magnetic field, and you generate electricity.

How do electric generators work?

In practice, an Electric Generator uses mechanical energy—like a spinning turbine—to rotate a coil inside a magnetic field. This movement generates EMF, which pushes electrons through the circuit, creating current. Depending on the design, it can produce AC or DC power.

What is the working principle of an electric motor and generator?

The key difference is direction of energy flow. A generator converts mechanical energy into electricity using Electromagnetic induction. A motor does the opposite—it uses electrical energy to produce motion. Both rely on magnetic fields and conductors, but their energy conversions move in reverse directions.

What is the mechanism of a generator?

The mechanism of an Electric Generator relies on Electromagnetic induction. When a coil of wire (the armature) spins inside a magnetic field, it cuts through magnetic lines of force. This movement induces EMF, causing current to flow. A rotor (the spinning part) moves the coil, while the stator holds the magnetic field. Together, they convert mechanical motion into electricity—efficiently and reliably.

What is the working principle of function generator?

Unlike a power generator, a function generator is an electronic device used in labs to produce repeating signals—like sine, square, or triangle waves. It doesn’t rely on Electromagnetic induction. Instead, it uses electronic circuitry (often involving oscillators and amplifiers) to simulate different waveforms. These waveforms are essential for testing other devices, not for generating usable electric power like an Electric Generator does.