Contents

Have you ever wondered how an invisible electric current can detect cracks in metal or help elevators stop safely? Welcome to the world of eddy currents—a fascinating phenomenon that blends physics and real-world functionality. In this article on the Tech4Ultra Electrical website, I’ll break down the basics of eddy current theory and walk you through some of the most practical eddy current applications. By the end, you’ll not only understand how these currents work but also see how they’re quietly powering safety and innovation in our everyday lives.

The Science Behind Eddy Currents

Faraday’s Law and electromagnetic induction

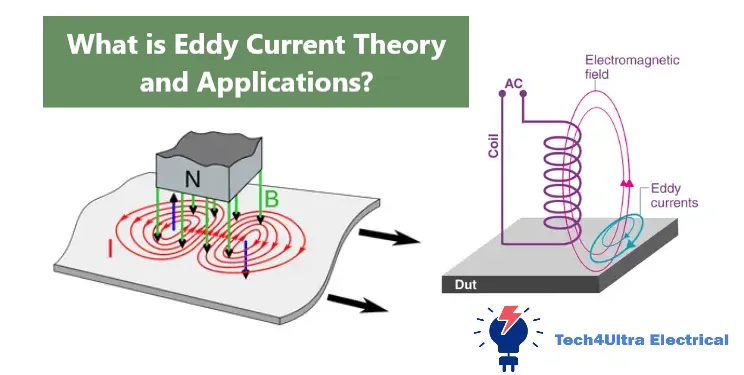

The first time I heard about eddy currents, I was sitting in a high school physics lab watching a copper ring magically repel a falling magnet. It felt like magic—until I learned it was pure science. According to Faraday’s Law, any change in the magnetic environment of a coil of wire—or any conductor—induces an electromotive force (EMF). This is the heart of eddy current theory: moving magnets near metal creates swirling currents inside the metal. These aren’t external currents we wire up—they’re self-generated, closed-loop responses to changing magnetic fields.

How eddy currents are formed in conductors

Imagine dropping a strong magnet through a hollow copper pipe. It doesn’t fall normally—it slows down. That’s because the changing magnetic field induces eddy currents in the pipe walls. These currents circulate in loops perpendicular to the magnetic field and oppose the motion that created them. I remember repeating this experiment over and over, fascinated that metal could behave almost like a brake without touching anything.

Role of Lenz’s Law

This is where Lenz’s Law comes in. It states that eddy currents always act to oppose the cause that created them. It’s like nature’s way of saying, “Not so fast.” These currents create their own magnetic fields, which resist the movement of the magnet or changing field. Understanding this helped me realize why eddy current applications in braking systems and electromagnetic shielding are so effective—they’re not just reacting, they’re resisting with purpose.

Read Also: Transformer Efficiency Explained: Calculation, Losses, and Optimization Strategies

Key Characteristics of Eddy Currents

Direction and flow in loops

One of the things that first caught my attention when studying eddy currents is their loop-like behavior. These currents don’t flow in a straight line like conventional electricity. Instead, they swirl in circular paths—like tiny whirlpools inside metal. Their direction is always in opposition to the change in magnetic field that produced them, as described by eddy current theory. It’s not random—there’s a clear pattern governed by electromagnetic principles.

Heat generation

What surprised me most when experimenting with eddy currents was how much heat they can produce. Place a metal plate near a rapidly changing magnetic field, and you’ll feel it get warm. That’s the result of electrical resistance. This heating effect isn’t just a side effect—it’s a crucial part of many eddy current applications like induction cooking and industrial metal heating processes.

Skin effect and proximity effect

High-frequency eddy currents don’t spread evenly. Instead, they concentrate near the surface of the conductor—a phenomenon known as the skin effect. Add to that the proximity effect, where nearby conductors influence each other’s current paths, and things get complex quickly. These effects are critical to understand in transformer design and high-frequency electronics.

Factors Affecting Eddy Current Formation

Material conductivity

When I first tried experimenting with eddy currents, I didn’t realize how much the type of metal would matter. But it turns out, the more conductive the material, the stronger the currents. Copper and aluminum, for example, allow eddy currents to form easily due to their low electrical resistance. In contrast, stainless steel or iron generates weaker currents unless you’re working with intense magnetic fields. This is a key principle in eddy current theory and one that explains why certain materials are chosen in eddy current applications like braking systems or induction heating.

Magnetic flux strength

Another critical factor is the strength of the magnetic field. A stronger magnetic flux means a higher rate of change, which leads to more intense eddy currents. This principle is why powerful electromagnets are used in testing and sensing applications.

Frequency of the changing field

Higher frequencies also lead to stronger eddy currents, but with added quirks like the skin effect becoming more prominent. In my experience, tuning the frequency is a balancing act—too low and the response is weak; too high and the current stays at the surface, limiting penetration. This plays a vital role in optimizing performance across various eddy current applications.

Modern Applications of Eddy Currents

Eddy current braking systems (trains, amusement rides)

I remember the first time I rode a high-speed train in Japan and noticed how smooth the braking felt—no screeching, no jerks, just silence. That was my introduction to eddy current braking. In systems like these, when a conductor passes through a magnetic field, eddy currents are generated, producing resistance that slows the object without physical contact. This contactless braking is used in roller coasters too. It’s safe, low-maintenance, and incredibly reliable. It’s one of the coolest eddy current applications I’ve ever experienced.

Induction heating (cooking, metalworking)

You’d be surprised how often eddy currents are hiding in your kitchen. Induction stoves work by generating eddy currents in the metal cookware. The resistance of the pot itself turns the electrical energy into heat directly, without warming the stovetop. It’s efficient and fast—boiling water feels almost instant. In metalworking, I once saw an induction furnace melt steel blocks in minutes using the same principle. Eddy current theory in action again, just with a lot more voltage and drama.

Eddy current sensors and non-destructive testing

In industrial settings, eddy current sensors are like X-ray vision. I worked on a project inspecting turbine blades where the tiniest cracks had to be detected without damaging the part. We used handheld probes that sent alternating magnetic fields into the metal. Any disruption in the flow of eddy currents—caused by cracks or corrosion—would change the signal. This method, known as non-destructive testing, is widely used in aerospace, automotive, and manufacturing sectors. It’s a perfect blend of precision and physics.

Energy meters and magnetic levitation systems

Even your utility meter may rely on eddy currents. Older analog energy meters use rotating disks that interact with magnetic fields to measure electricity consumption. The resistance created by eddy currents slows the disk based on your energy use. On a larger scale, maglev trains—those floating trains with zero friction—use eddy current applications to achieve magnetic levitation. It’s not just about speed, but efficiency and minimal wear and tear.

Eddy currents may seem like a textbook topic, but they quietly support some of the most advanced technologies we use every day. From your kitchen to outer space, they’re spinning silently, keeping systems safer, smarter, and smoother.

Innovative Uses in Emerging Technologies

Magnetic damping in aerospace

When I first visited an aerospace lab during a university field trip, I was stunned to see engineers using eddy currents to stabilize spacecraft components. No motors, no friction—just magnetism. This technique, known as magnetic damping, uses eddy currents to slow or control motion in sensitive instruments like satellites and telescopes. When a conductive surface moves through a magnetic field, the resulting eddy currents create a counter force, gently dampening oscillations. It’s silent, reliable, and perfect for the vacuum of space.

Magnetic levitation transport (Maglev trains)

One of the most thrilling moments of my life was riding a Maglev train in Shanghai. Gliding above the tracks at over 400 km/h, I realized I was witnessing eddy current applications at their peak. In these systems, powerful magnets induce eddy currents in guideway rails, generating lift and stabilizing the train without physical contact. The result? Virtually no friction and mind-blowing acceleration. It’s not just a ride—it’s the future of urban mobility based on eddy current theory.

Smart energy systems

In the realm of energy tech, eddy currents are becoming key players. I’ve seen how smart meters and renewable energy converters rely on eddy current sensors to measure load and efficiency without direct contact. They’re durable, low-maintenance, and provide real-time data—exactly what our evolving power grids need. As more systems shift to automation, these sensors will be crucial in maintaining balance, preventing overloads, and optimizing energy flow.

Challenges and Drawbacks of Eddy Currents

Power losses

When I first started working with transformers, I quickly learned that eddy currents aren’t always helpful. In fact, one of their biggest drawbacks is energy loss. These swirling currents generate heat as they move through conductive materials, and that translates directly into wasted power. It’s a hidden drain, especially in devices meant to run continuously like electric motors or power converters. Eddy current theory makes it clear—more motion in a magnetic field means more induced current, even when you don’t want it.

Overheating in electrical machines

In one project, we had to shut down an industrial motor because it was overheating—not due to load, but because of uncontrolled eddy currents. They were forming inside the iron core and heating it up from the inside. Without proper design, these currents can quickly build up and damage insulation or reduce equipment lifespan.

Impact on transformer efficiency

Transformers are especially sensitive to eddy current losses. That’s why their cores are often made from laminated steel, which breaks up the path of the currents and limits heat buildup. Still, even with lamination, eddy currents can lower overall efficiency and require extra cooling measures. It’s a constant battle between magnetic performance and energy conservation.

Techniques to Minimize Eddy Current Losses

Laminated magnetic cores

The first time I opened up a transformer, I was surprised to see that its core wasn’t solid—it was made of thin sheets stacked together. That’s when I learned about one of the most effective methods for minimizing eddy currents: lamination. By layering the core with insulating coatings between each sheet, the path for eddy currents is interrupted. Less current means less heat. It’s a simple solution rooted deeply in eddy current theory, and it works incredibly well in motors, transformers, and generators.

Use of ferrites and powdered metals

In high-frequency applications, laminated steel doesn’t cut it. That’s where ferrites and powdered metals come in. I once worked on a project involving a wireless charger where standard materials caused major heat issues. We switched to ferrites—ceramic materials with low conductivity—and the problem disappeared. Because they resist eddy current formation, ferrites are ideal for electronics, radio-frequency devices, and compact magnetic cores.

Slotted cores

Another clever trick I’ve seen is slotted cores. Instead of being solid, these cores are cut with air gaps or slots that interrupt eddy current flow. We used this method in a magnetic brake system to improve efficiency and reduce unwanted heating. Slotted designs are especially useful in rotors and stators, where circulating eddy currents can build up fast. They reduce losses while preserving magnetic function—an elegant engineering workaround.

Watch Also: Star Delta Starter: Comprehensive Guide to Working, Circuits, and Applications

Comparison Table: Eddy Currents vs. Other Inductive Effects

When I first started studying electromagnetic behavior, I often confused eddy currents with other inductive phenomena like the skin effect, proximity effect, and hysteresis. While they all result from changing magnetic fields, each has unique behaviors and consequences. Understanding these distinctions is crucial for engineers working with power electronics, transformers, or high-frequency circuits. Here’s a simple table that helped me sort them out clearly:

| Phenomenon | Main Cause | Effect | Typical Impact |

|---|---|---|---|

| Eddy Currents | Changing magnetic fields in conductors | Circulating loops of current | Power loss, heating, magnetic damping |

| Skin Effect | High-frequency AC currents | Current concentrates near surface | Increased resistance, efficiency loss |

| Proximity Effect | Magnetic field of nearby conductors | Distorted current paths | Uneven heating, reduced current capacity |

| Hysteresis | Lagging magnetization in materials | Energy loss per cycle | Core heating, inefficiency in transformers |

Conclusion

Eddy currents may have started as a side effect of electromagnetic induction, but today they’ve evolved into powerful tools across industries. From frictionless eddy current applications in high-speed trains and non-destructive testing to heat generation in induction stoves, their real-world utility is undeniable. We’ve explored how eddy current theory connects to Faraday’s and Lenz’s Laws, the factors influencing their formation, and how engineers work to minimize their drawbacks like energy loss and overheating.

Looking ahead, the potential for eddy currents in emerging tech is massive. Think smarter sensors, cleaner transport, and more efficient energy systems. Whether you’re an engineer, student, or curious mind, understanding eddy currents opens the door to both solving practical problems and innovating the future. Keep an eye on this quiet force in electromagnetism—it’s not done surprising us yet.

FAQs

What do you mean by eddy current?

Eddy currents are circular electric currents induced within conductors when exposed to a changing magnetic field. These currents flow in closed loops, perpendicular to the magnetic field, and are a direct result of Faraday’s Law of electromagnetic induction.

What do eddy currents cause?

Eddy currents can lead to several effects. On the downside, they cause unwanted heat generation and power loss in electrical machines and transformers. On the upside, they are used beneficially in eddy current applications like braking systems, metal detectors, and non-destructive testing tools.

What is basic eddy current?

The basic concept of eddy currents involves loops of electric current generated in a conductor when it experiences a change in magnetic field. These currents oppose the change that caused them, as explained by Lenz’s Law, and are a key aspect of eddy current theory.

What is the law of eddy current?

The behavior of eddy currents is governed by both Faraday’s Law and Lenz’s Law. Faraday’s Law explains how a changing magnetic field induces an EMF in a conductor, while Lenz’s Law states that the induced current will always oppose the change in magnetic flux that created it.

What is eddy current examples?

Common examples of eddy current applications include electromagnetic braking in high-speed trains and roller coasters, where eddy currents are used to slow motion without physical contact. Another is induction cooktops, where eddy currents heat metal cookware directly. In industrial settings, they’re used for non-destructive testing and metal sorting.

What is the eddy effect?

The eddy effect refers to the phenomenon where circulating electrical currents are induced in a conductor due to a changing magnetic field. This effect results in resistance to motion, heat generation, and energy loss, but is also harnessed for practical uses such as braking, heating, and sensing in various eddy current technologies.

4 thoughts on “Star Delta Starter: Comprehensive Guide to Working, Circuits, and Applications”