Contents

Ever wondered why your electricity bill seems a little too high, or why industrial equipment doesn’t always perform at its peak? The answer might lie in a concept called transformer efficiency.

At its core, transformer efficiency refers to how effectively a transformer converts input electrical power into usable output power without unnecessary energy losses. Ideally, we want this number to be as close to 100% as possible—but in real life, that’s rarely the case. Some energy always escapes as heat, noise, or through core and copper losses.

Understanding the efficiency of transformer systems is critical, whether you’re managing an industrial plant or simply relying on your home’s electrical grid. In industrial settings, even a 1% efficiency loss can translate into thousands of dollars in wasted energy each year. On the home front, inefficient transformers in devices or systems can lead to higher power consumption and reduced appliance lifespan.

So yeah, when it comes to saving money and improving system performance, transformer efficiency isn’t just technical jargon—it’s a big deal.

What is Transformer Efficiency?

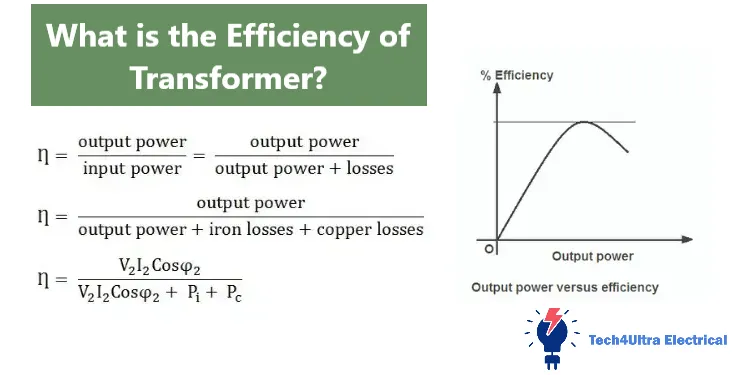

Transformer efficiency is a measure of how well a transformer converts the input electrical power into output power without significant losses. It’s usually expressed as a percentage and calculated using this simple formula:

Efficiency (%) = (Output Power / Input Power) × 100

In every transformer, the input power is never fully equal to the output power because of inherent losses—mostly copper loss (in the windings) and iron loss (in the core). These losses cause the output power to be slightly less than the input, resulting in efficiency being less than 100%.

This is where the relationship between input, output, and power loss becomes crucial. Simply put:

- Input Power = Output Power + Power Loss

The smaller the power loss, the higher the efficiency of transformer. In real-world applications, this efficiency directly impacts energy costs and performance. For example, in large-scale industrial settings, even a 2% inefficiency can cost thousands in wasted electricity over time.

At home, inefficient transformers in appliances can quietly drain your wallet by increasing your monthly utility bills. That’s why paying attention to transformer efficiency isn’t just for engineers—it’s for anyone who values energy savings and system reliability.

Read Also: Star Delta Starter: Comprehensive Guide to Working, Circuits, and Applications

Types of Losses in Transformers

To truly understand transformer efficiency, we need to dive into the different types of losses that eat away at performance. These losses are what prevent transformers from being 100% efficient. Let’s break them down:

Core (Iron) Loss

This loss happens in the transformer’s iron core and is constant, regardless of load. It includes two main components: hysteresis and eddy current losses.

Hysteresis Loss

This occurs due to the magnetization and demagnetization of the core as the AC current alternates. It’s proportional to frequency and the type of core material.

Eddy Current Loss

When magnetic fields induce circulating currents in the core, they cause heat—this is eddy current loss. Laminating the core helps reduce it significantly.

Copper Loss

This is the heat produced due to the resistance in the transformer windings. Unlike core losses, copper loss varies with the square of the load current. More load = more heat = less efficiency of transformer.

Dielectric Loss

Often overlooked, this loss occurs in the transformer’s insulation system. While usually small, it can become significant in high-voltage equipment or under extreme conditions.

Stray Losses

These are random losses from leakage flux that induce currents in nearby conductive parts like the tank or supporting structures. They’re tricky to measure but can affect overall transformer efficiency.

Comparison Table: Losses Under Different Load Conditions

| Type of Loss | No Load | Half Load | Full Load |

|---|---|---|---|

| Core (Iron) Loss | Constant | Constant | Constant |

| Hysteresis Loss | Constant | Constant | Constant |

| Eddy Current Loss | Constant | Constant | Constant |

| Copper Loss | Minimal | Moderate | Maximum |

| Dielectric Loss | Negligible | Negligible | Low |

| Stray Losses | Negligible | Variable | High |

By understanding these different forms of loss, you’re better equipped to improve transformer efficiency and make smarter choices in design, purchase, or operation.

How to Calculate Transformer Efficiency

Calculating transformer efficiency isn’t rocket science—it just takes knowing the right formulas and understanding how losses impact performance under different load conditions. Let’s break it down simply.

Key Formulas

- No-Load Efficiency:

Efficiency = (Output Power / (Output Power + Core Loss)) × 100 - Full-Load Efficiency:

Efficiency = (Output Power / (Output Power + Copper Loss + Core Loss)) × 100 - Partial-Load Efficiency:

Efficiency = (x × Rated Output) / (x × Rated Output + x² × Copper Loss + Core Loss) × 100

(Where x is the fractional load, e.g., 0.5 for half load)

Step-by-Step Calculation Guide

- Determine your transformer’s rated output (in watts or kVA).

- Find the values for copper loss and core loss (usually from the datasheet).

- Select your load condition: no-load, full-load, or partial-load.

- Plug values into the relevant formula above.

- Calculate the result to get your efficiency of transformer.

Example: A 100 kVA transformer with 1.5 kW core loss and 2.5 kW copper loss at full load:

Efficiency = (100 / (100 + 1.5 + 2.5)) × 100 = (100 / 104) × 100 ≈ 96.15%

Bonus: Online Calculator

If math isn’t your thing, try using this Transformer Efficiency Calculator. Just enter your values, and it handles the rest—quick and easy!

Understanding and calculating transformer efficiency helps you monitor system health and optimize energy use with real numbers.

Transformer Efficiency at Different Loads

Transformer efficiency isn’t static—it changes depending on the load. This means how much power the transformer is handling directly affects how efficient it is at doing its job.

At light loads (say 10–30% of rated capacity), core losses dominate, making efficiency relatively low. As the load increases, copper losses begin to play a bigger role. There’s usually a sweet spot—often around 75% to 100% load—where the balance of losses leads to peak efficiency of transformer.

Here’s a simple way to think about it:

- Low load: High core loss impact, low copper loss.

- Medium load: Balanced core and copper loss, peak efficiency zone.

- Full load: Higher copper loss, but still high efficiency if well-designed.

Check out the efficiency trend in the table below:

| Load Level (%) | Efficiency (%) |

|---|---|

| 10% | 85% |

| 25% | 90% |

| 50% | 94% |

| 75% | 96% |

| 100% | 95.5% |

As shown, the efficiency of transformer typically peaks just before full load and slightly dips as copper losses become dominant. Designing systems to operate near peak efficiency load can save both energy and money.

Condition for Maximum Transformer Efficiency

Ever wondered when a transformer hits peak performance? The golden rule is simple: transformer efficiency is at its maximum when copper loss equals iron loss.

This is the “sweet spot” where the total energy wasted in both the windings and the core is minimized. Mathematically, it looks like this:

Copper Loss = Iron Loss

Mathematical Proof (Simplified)

Let:

- Pcu = Copper loss

- Pi = Iron loss

- η = Efficiency

Efficiency η = Output / (Output + Pcu + Pi)

To find the condition for maximum η, we derive η with respect to load current and set the derivative to zero. This yields:

Pcu = Pi

In plain language: you get max efficiency of transformer when the power wasted as heat in the copper equals the power lost due to magnetic effects in the core.

Practical Significance

For engineers and technicians, this condition isn’t just theory—it’s a design and maintenance checkpoint. When transformers are consistently operated near this balance point, they perform better, last longer, and save money.

Maintenance pros use this principle to set load thresholds and detect inefficiencies. For example, if copper losses start exceeding iron losses too early, it could signal winding degradation or cooling issues.

So next time someone mentions transformer losses, remember—it’s not about eliminating them completely, it’s about balancing them for peak transformer efficiency.

Watch Aslo: Understanding Space Charge: Effects, Laws, and Applications in Modern Electronics

Real-World Example and Calculation

Let’s bring transformer efficiency to life with a real-world example. Suppose we have a distribution transformer rated at 200 kVA, operating at full load. The given losses are:

- Core (Iron) Loss: 1.6 kW

- Copper Loss: 2.4 kW

We want to calculate the efficiency of transformer at full load with a power factor of 0.85 (lagging).

Step-by-Step Calculation

- Determine Output Power:

Output = 200 × 0.85 = 170 kW - Calculate Total Losses:

Total Loss = 1.6 + 2.4 = 4.0 kW - Find Input Power:

Input = Output + Loss = 170 + 4.0 = 174 kW - Efficiency:

Efficiency = (Output / Input) × 100 = (170 / 174) × 100 ≈ 97.7%

This means that only 2.3% of the energy is lost, which is actually very efficient for a typical power distribution transformer.

Bonus Tool: Excel Calculator

Want to speed things up? Download our Excel Transformer Efficiency Calculator where you just plug in your values and let it do the math!

Having a real example shows that understanding transformer efficiency isn’t just academic—it’s essential for optimizing energy use in real applications.

Factors Affecting Transformer Efficiency

Transformer efficiency isn’t set in stone—it fluctuates depending on several real-world factors. If you’re wondering why two identical transformers perform differently, here’s what could be behind it:

1. Ambient Temperature

High temperatures increase the resistance of copper windings, which in turn boosts copper losses. Poor ventilation or installation in hot environments can degrade the efficiency of transformer noticeably over time.

2. Load Profile

Transformers aren’t always running at full load. Frequent underloading leads to disproportionate core loss, while sudden spikes can increase copper losses. Maintaining a steady, optimal load improves long-term efficiency.

3. Quality of Core Material

Using high-grade silicon steel or amorphous metal in the core can significantly reduce hysteresis and eddy current losses. Lower-quality materials result in higher constant losses and lower efficiency—even with good design.

4. Maintenance Frequency

Dirty or corroded connections, worn insulation, and poor oil quality can all reduce transformer efficiency. Regular testing, oil replacement, and cleaning ensure optimal performance and prevent avoidable energy losses.

In short, it’s not just about design specs—external conditions and upkeep play a massive role in keeping your transformer energy-smart and cost-effective.

How to Improve Transformer Efficiency

Improving transformer efficiency isn’t just about upgrading hardware—it’s about smarter operation and proactive care. Whether you manage industrial systems or maintain local distribution units, these strategies can significantly boost performance:

1. Use of Amorphous Core Transformers

Unlike traditional silicon steel cores, amorphous metal cores have much lower hysteresis loss. They’re ideal for applications with high no-load operation, reducing core losses by up to 70%. While slightly pricier, they pay off quickly in energy savings.

2. Load Management

Keeping the transformer operating near its optimal load (usually 70–80% of full capacity) maximizes the efficiency of transformer. Avoid overloading, which increases copper loss, and underloading, which makes core loss dominant.

3. Periodic Maintenance

Dust buildup, loose connections, or degraded insulation can quietly kill efficiency. Routine maintenance—like oil testing, thermal scanning, and physical inspection—keeps the system in top shape.

4. Monitoring Tools for Predictive Diagnostics

Modern sensors and IoT-based diagnostics can track temperature, voltage, and current in real-time. This allows for early fault detection and prevents performance drops before they impact efficiency.

In short, improving transformer efficiency isn’t a one-time fix—it’s a cycle of good design, smart loading, consistent care, and real-time awareness. Start with even one of these practices, and you’re already ahead of the curve.

Transformer Efficiency vs Performance

Transformer efficiency is a major performance metric—but it’s not the only one that matters. While efficiency focuses on how much power is lost during operation, other parameters like voltage regulation and reliability also play critical roles.

Voltage regulation measures the transformer’s ability to maintain a constant output voltage under varying load conditions. A transformer could be highly efficient but still exhibit poor voltage regulation, which may cause equipment malfunctions or instability.

Then there’s reliability—the ability of the transformer to operate over long periods without failure. High efficiency of transformer doesn’t guarantee fewer breakdowns if the unit isn’t properly maintained or is exposed to extreme conditions.

In essence, a high-performing transformer strikes the right balance: strong efficiency, tight voltage control, and dependable uptime. All three must align to ensure optimal electrical performance.

Conclusion

Transformer efficiency may seem like a technical detail, but it has a massive impact on both operational costs and energy sustainability. From understanding different types of losses to calculating and optimizing performance, we’ve covered the essentials every engineer, technician, or energy-conscious user should know.

Key takeaways? Efficiency peaks when copper loss equals core loss, and smart choices—like using quality materials and maintaining optimal loads—can make a noticeable difference. Also, don’t underestimate the value of regular maintenance and predictive monitoring; these practices help detect problems early and keep the system running smoothly.

In today’s energy-driven world, optimizing the efficiency of transformer units isn’t just good engineering—it’s smart business and smart living. Stay proactive, monitor consistently, and your transformer will reward you with performance, savings, and reliability for years to come.

FAQs

How to calculate transformer efficiency?

You can calculate transformer efficiency using the formula: Efficiency (%) = (Output Power / Input Power) × 100. Make sure to account for both copper and core losses to get an accurate result, especially under different load conditions.

What is the efficiency of a 3 phase transformer?

The efficiency of transformer in three-phase systems typically ranges from 95% to 99%, depending on design quality, loading, and loss characteristics. They are generally more efficient than single-phase transformers in high-power applications.

Is a transformer 100% efficient?

No, a transformer cannot be 100% efficient. Some energy is always lost due to core (iron) losses and copper losses. Even top-tier units max out around 99% under ideal conditions.

What is the formula for efficiency?

The general formula is: Efficiency (%) = (Output Power / Input Power) × 100. For transformers, this typically translates to: Efficiency = (Output) / (Output + Losses) × 100, where losses include both copper and iron losses.

Can a transformer be 100% efficient?

No. In theory, it’s impossible for any real-world transformer to be 100% efficient due to inevitable core and copper losses. The goal is to minimize these losses as much as possible.

What is the typical efficiency of a distribution transformer?

Most modern distribution transformers operate at an efficiency of transformer between 95% and 98.5%, depending on load and design quality.

How can I improve the efficiency of my transformer?

Use amorphous core transformers, manage loads wisely, conduct regular maintenance, and install monitoring systems for predictive diagnostics.

Does transformer efficiency vary with load?

Yes. Transformer efficiency is usually highest at around 70–100% of full load. At very low loads, core losses dominate; at very high loads, copper losses increase.

Why is transformer efficiency important?

Higher efficiency means less energy waste, lower electricity bills, longer equipment lifespan, and a more sustainable energy footprint—especially in large-scale systems.