Contents

I still remember the first time I stumbled across a thermoelectric generator during a late-night YouTube binge on DIY energy hacks. I was amazed — a device that could turn heat directly into electricity? No moving parts, no noise, just pure magic… or so I thought.

Turns out, it’s not magic. It’s physics. At the heart of this tech is the Seebeck effect, discovered back in 1821. It’s what makes Seebeck power generation possible: when there’s a temperature difference across certain materials, electricity starts to flow. That simple concept is now driving real innovation in modern energy systems.

What really hit me is how thermoelectric power generators can be used where traditional generators can’t. Think about space missions, remote sensors, or even wearable tech that harvests your body heat. I’ve seen small-scale models power LED lights just using the heat from a candle. It’s that accessible.

But the real importance of the thermoelectric effect lies in its potential to convert waste heat — like from car engines or industrial equipment — into usable energy. That’s game-changing in a world obsessed with sustainability.

So, if you’ve ever felt a laptop warming your legs or touched a hot exhaust pipe, you’ve felt energy escaping. Thermoelectric tech wants to catch it — and put it to work.

What are Thermoelectric Power Generators?

Let me tell you about the moment I first stumbled upon a thermoelectric power generator—and no, it wasn’t in a fancy lab. It was during a camping trip. My buddy whipped out this small device, placed it over our campfire, and, boom—charged his phone with it. My brain practically short-circuited with excitement. “You’re telling me we can make electricity from heat… like, from a fire?” I asked, almost spilling my instant coffee. That’s when I first learned about the Seebeck effect—a principle that felt like magic but was all science.

The magic behind these devices lies in the Seebeck effect, where a temperature difference between two different materials can generate an electric current. This isn’t some theoretical physics mumbo jumbo. It’s real, and it works. The hotter one side gets compared to the other, the more voltage you can squeeze out of it. This process is called Seebeck power generation, and it’s honestly one of the coolest (pun intended) ways to harvest energy.

Now, back to that fire-charging device. It was a compact thermoelectric generator—basically, a solid-state device that converts heat into electricity without any moving parts. You’ll find larger, more industrial versions in satellites, remote sensors, and even backup power systems in harsh environments. The appeal? Durability, no maintenance, and pure science doing its job.

How Seebeck Power Generation Works

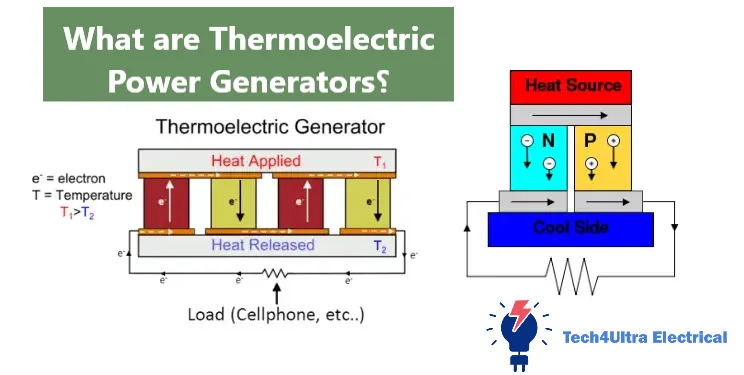

To break it down super simply:

- You apply heat to one side of a thermoelectric module.

- Keep the other side cool.

- Electrons start moving from hot to cold.

- BAM! You’ve got electricity.

But here’s the thing they don’t tell you: getting significant power isn’t easy. I tried building a DIY version once using cheap materials—and let’s just say I lit up a single LED. Not exactly home-powering glory, but it was a start.

That’s what makes thermoelectric power generators so fascinating. They turn waste heat—something we usually ignore—into useful power. Whether you’re looking at off-grid survival tools or futuristic spacecraft, the Seebeck effect is doing heavy lifting behind the scenes.

Tips if You’re Thinking of Trying It:

- Use metals with a high Seebeck coefficient (like bismuth telluride).

- The greater the temperature difference, the more efficient the output.

- Don’t expect miracles—these generators are about low, steady power over time.

- Great for trickle-charging batteries, powering sensors, or emergency energy.

“The best way to predict the future is to invent it.” —Alan Kay

And maybe, just maybe, thermoelectric power generators are a small but mighty part of that future.

The Science Behind the Seebeck Effect

The Seebeck effect might sound like something out of a physics textbook — and technically, it is. But it’s also one of those principles that’s quietly transforming how we think about energy. Named after Thomas Johann Seebeck, who discovered it in 1821, this effect occurs when two different conductive materials form a closed loop and their junctions are kept at different temperatures. The result? A voltage is generated, and that voltage can be used to power real-world devices.

At its core, the Seebeck effect is all about electrons responding to temperature. When there’s a thermal gradient across a conductor, charge carriers like electrons or holes move from the hot side to the cold side. This movement creates an electric potential. That’s how a thermoelectric generator starts doing its job — capturing that potential and turning it into usable electricity.

It’s not just theory. This is the principle behind thermoelectric power generators used in NASA spacecraft, where solar power isn’t reliable. Or in wearable devices that generate electricity from body heat. Even in remote sensors placed in harsh environments where no batteries or wires would survive.

The real genius of Seebeck power generation lies in its simplicity. No moving parts. No fuels. Just temperature differences and the clever use of conductive materials. Whether it’s a thermoelectric effect in action at a steel plant reclaiming waste heat or a tiny module on a hiking backpack, it all begins with this one elegant scientific phenomenon.

Read Also: Star Delta Starter: Comprehensive Guide to Working, Circuits, and Applications

Thermoelectric Effect vs Seebeck Effect

Let’s clear up the confusion — the thermoelectric effect isn’t just one thing. It’s actually a family of related phenomena, and the Seebeck effect is just one member of the crew. If the Seebeck effect is the one that generates voltage from heat, then its siblings — the Peltier and Thomson effects — handle the rest of the thermoelectric behavior.

Here’s the breakdown: the Seebeck effect is all about converting a temperature difference into electricity, which is the principle behind any good thermoelectric generator. But flip that around — if you pass current through two different materials, they absorb or release heat at the junctions. That’s the Peltier effect. It’s actually used in thermoelectric cooling systems. And the Thomson effect? It’s a bit more subtle — it describes how heat is absorbed or released when current flows through a single conductor with a temperature gradient.

So, when people say “thermoelectric effect,” they often mean the entire group. But in the context of Seebeck power generation, the Seebeck effect is the key player. It’s the one responsible for turning heat differences into electric power, while its counterparts help explain the broader behavior of thermal-electric interactions.

Understanding this trio helps you see the full picture — and appreciate the precision behind modern thermoelectric power generators.

How Thermoelectric Generators Work

So, how does a thermoelectric generator actually turn heat into electricity? It all starts with a simple concept: temperature difference. The key component in the setup is the thermoelectric module, which houses materials specifically chosen for their ability to exploit the Seebeck effect.

Here’s a step-by-step breakdown of what happens:

- A heat source is applied to one side of the thermoelectric module. This could be anything — engine heat, body warmth, sunlight, or industrial waste heat.

- The other side of the module is kept cooler, usually with a heat sink or a cooler environment.

- Inside the module are pairs of thermoelectric materials — typically semiconductors — arranged in a series of “legs” connected electrically in series and thermally in parallel.

- As the temperature difference develops, the Seebeck effect kicks in, causing electrons to flow from the hot side to the cold side. This creates a voltage across the module.

- Connect an electrical load, and voilà — the voltage drives current, and you’ve got power.

It’s a quiet, solid-state system — no moving parts, no fuels, just physics doing its job. That’s why thermoelectric power generators are so valuable in space missions, remote sensors, or any application where maintenance is a hassle.

But let’s be real: efficiency is a tough nut to crack. Most commercial thermoelectric generators convert only about 5–8% of the heat they absorb into electricity. That’s because of limitations in the thermal conductivity and electrical resistance of the materials used.

Researchers are constantly developing better thermoelectric materials — ones that can handle higher temperatures and conduct electricity without letting too much heat leak through. That’s the key to boosting efficiency and unlocking more use cases for Seebeck power generation.

Types of Thermoelectric Materials

If you’ve ever wondered what makes a thermoelectric generator tick, the answer lies in its core — the materials. Not just any metal will do. To exploit the Seebeck effect effectively, you need materials that can juggle three tough jobs: high electrical conductivity, low thermal conductivity, and a strong thermoelectric response. That combo is rare, and that’s why material science is so critical in thermoelectric power generator design.

One of the most commonly used materials is bismuth telluride (Bi2Te3). It’s the go-to choice for room-temperature thermoelectric effect applications like portable coolers and small-scale generators. It’s reliable and well-studied, but its efficiency drops sharply at higher temperatures.

For hotter applications — think automotive exhausts or industrial heat recovery — lead telluride (PbTe) is a solid performer. It handles high temperatures better and is more efficient under those conditions. However, lead is toxic and poses environmental challenges, especially for large-scale systems.

Then there are advanced materials like skutterudites and clathrates, which promise higher performance but come with high costs and complex fabrication. Silicon-germanium alloys are also used, especially in aerospace, where reliability and temperature tolerance are more important than raw efficiency.

Here’s a quick snapshot:

- Bismuth telluride: Best for low-temperature use, low toxicity, moderate efficiency.

- Lead telluride: Suitable for high-temp, high efficiency, but toxic.

- Skutterudites & Clathrates: High performance, costly and complex.

- Silicon-germanium: Rugged and reliable, ideal for space tech.

Choosing the right thermoelectric materials is a balancing act between efficiency, temperature range, cost, and environmental impact — and that’s what defines the real-world potential of Seebeck power generation.

Applications of Thermoelectric Generators

What really makes thermoelectric generators exciting is how versatile they are. Thanks to the Seebeck effect, they can produce electricity just about anywhere there’s heat — and that opens the door to a wide range of real-world uses. Let’s break down where you’ll actually find thermoelectric power generators doing their thing.

1. Automotive Industry

Cars waste a ridiculous amount of energy as heat — especially from the exhaust. Thermoelectric generators are being integrated into vehicles to reclaim that heat and convert it into power. This helps improve fuel efficiency and reduce load on the alternator. BMW and Toyota have tested prototypes, and it’s only a matter of time before this tech becomes mainstream.

2. Aerospace and Military

Space? No sunlight? No problem. NASA has used thermoelectric power generators for decades in deep space missions. The Mars rovers, for example, use heat from decaying plutonium to generate electricity via the thermoelectric effect. In military settings, the same tech helps power sensors and communication devices in harsh environments where batteries just won’t cut it.

3. Consumer Electronics

Imagine charging your smartwatch from body heat — it’s already happening. Wearable tech companies are experimenting with thermoelectric modules that use the temperature difference between your skin and the air to generate power. It’s not just cool; it’s useful when you’re off-grid or don’t want to worry about charging cables.

4. Industrial Waste Heat Recovery

Factories and power plants produce tons of waste heat every second. That’s energy going straight out the window. With Seebeck power generation, some companies are capturing this heat and turning it into supplemental electricity. It’s a small change with big savings — especially in energy-intensive industries like steel or cement.

From outer space to your wrist, the potential of thermoelectric generators is just heating up.

Watch Also: Understanding Space Charge: Effects, Laws, and Applications in Modern Electronics

Real-World Case Studies

It’s one thing to talk about theory — but seeing thermoelectric generators in action is where things get exciting. Several companies and industries have already adopted Seebeck power generation technology with some impressive results. Let’s take a look at a few real-world case studies where the thermoelectric effect has gone from lab to life.

BMW and the Automotive Sector

BMW has been experimenting with thermoelectric power generators in its high-efficiency vehicles. By mounting TEG units on the exhaust system, they’ve managed to reclaim waste heat and convert it into electricity. This reduces the load on the alternator, improving fuel economy by up to 5%. Not a massive number at first glance, but across millions of vehicles, it adds up to serious savings and emissions cuts.

NASA and Deep Space Missions

Few organizations rely on the thermoelectric effect more than NASA. Its Voyager, Curiosity, and Perseverance missions all use radioisotope thermoelectric generators (RTGs) that convert the heat from decaying plutonium into electrical energy. These units provide consistent power for years without sunlight or maintenance — an absolute game changer for long-term missions in deep space.

TEGma and Industrial Efficiency

TEGma, a company specializing in industrial energy solutions, has partnered with factories to deploy thermoelectric modules on high-temperature machinery. One of their clients, a glass manufacturing plant, saw a 6% reduction in electricity usage by recovering waste heat using TEG systems. That translates to lower bills and reduced carbon emissions.

These aren’t hypotheticals — they’re proof that Seebeck power generation works. And as material science improves, so will the reach and results of this powerful tech.

Advantages of Thermoelectric Generators

Sometimes, the best technologies are the ones that just… work. And that’s exactly why thermoelectric generators are so appealing. Thanks to the Seebeck effect, they convert heat into electricity without any moving parts. That means no friction, no mechanical wear, and — best of all — silent operation.

These devices are rock solid. With no gears to grind or fans to spin, the lifespan of a thermoelectric power generator can stretch into decades, especially in space or remote industrial environments. NASA’s RTGs, for example, have powered missions for over 40 years with minimal performance loss. That kind of reliability is rare in energy tech.

Another huge perk is scalability. You can design thermoelectric modules to power something as small as a smartwatch or scale them up for waste heat recovery in factories. Their flexibility is unmatched — whether you’re charging a phone or supplementing power in a steel mill.

And let’s not forget sustainability. Seebeck power generation doesn’t burn fuel or release emissions. It simply harvests energy that would otherwise be wasted. That makes it a quiet hero in the fight against climate change — capturing lost energy and converting it into something useful.

In short, the thermoelectric effect delivers on simplicity, reliability, and green energy — all without making a sound.

Disadvantages and Challenges

As promising as thermoelectric generators are, they come with their fair share of baggage. The biggest drawback? Low efficiency. Most commercial thermoelectric power generators convert only about 5–8% of the heat they absorb into usable electricity. That’s a tough pill to swallow when compared to other technologies like internal combustion engines or solar panels.

The reason lies in the physics of the thermoelectric effect itself — it’s hard to find materials that have both high electrical conductivity and low thermal conductivity. Most materials either lose too much heat or don’t conduct electricity well enough to make the process efficient.

Then there’s the issue of high material cost. Premium thermoelectric materials like bismuth telluride and lead telluride aren’t exactly cheap. When you factor in the cost of rare or toxic elements and the specialized manufacturing process, the price tag can be a dealbreaker for large-scale deployment — especially in cost-sensitive sectors like consumer electronics or automotive.

Integration also isn’t always smooth. Adding thermoelectric modules to an existing system means designing for thermal management, heat sinks, and electrical routing. It’s not just plug-and-play. Plus, thermal cycling — repeated heating and cooling — can wear down even the best modules over time, especially in harsh environments.

Despite these challenges, researchers and companies continue to invest in better materials and smarter designs. If those hurdles can be cleared, Seebeck power generation could become a mainstream energy solution — not just a niche player.

Future Prospects and Innovations

The future looks hot — literally — for thermoelectric generators. With rising global interest in clean energy and sustainability, the pressure is on to squeeze more power from the Seebeck effect. Fortunately, science is stepping up, and the innovations on the horizon are pretty exciting.

First, let’s talk about emerging materials. Researchers are moving beyond traditional compounds like bismuth telluride and exploring new alloys and composites. Materials like tin selenide and magnesium silicide are showing promise with higher efficiency and lower toxicity. These could help bring down the cost and push thermoelectric power generator technology into wider use.

Then there’s nanotechnology. By engineering materials at the atomic scale, scientists can drastically improve thermal and electrical properties. For instance, nanostructured thermoelectric materials can better manage heat flow while boosting conductivity — a game changer for performance and efficiency.

These advances could make thermoelectric effect systems viable for broader industrial use, such as waste heat recovery on a massive scale. Imagine factories recycling their own heat to power machines, or data centers running on their own thermal output. That’s not science fiction — that’s the near future.

And let’s not forget the big picture: Seebeck power generation aligns perfectly with the green energy transition. It’s clean, scalable, and ideal for decentralized power systems. As nations push for carbon neutrality, thermoelectric modules may soon play a key role in bridging energy gaps — capturing the heat we already lose and turning it into electricity we actually need.

Comparison with Other Power Generation Methods

So how do thermoelectric generators stack up against other popular power sources? It’s a fair question — and the answer really depends on the use case. Let’s break it down.

Batteries vs Thermoelectric: Batteries store energy, but they need to be recharged or replaced. A thermoelectric generator, on the other hand, keeps going as long as there’s a heat source. It’s perfect for remote or long-term applications where battery swaps aren’t practical. But keep in mind: batteries still win on power density and initial cost.

Fuel Cells vs Thermoelectric: Fuel cells offer high efficiency and cleaner output than combustion engines. But they rely on a steady fuel supply and more complex systems. In contrast, Seebeck power generation is simpler, quieter, and can use waste heat — but it’s far less efficient. Thermoelectrics shine in places where simplicity and reliability are more critical than raw power.

Solar Panels vs Thermoelectric: Solar panels dominate the renewables scene with better efficiency and scalability. However, they need sunlight. Thermoelectric effect systems don’t — they just need heat, which makes them ideal in dark or extreme environments like space or underground operations. They can also complement solar, capturing energy when the sun isn’t shining.

Bottom line: thermoelectric power generators aren’t always the best — but they’re often the best fit when silence, durability, and waste-heat recovery matter most.

Conclusion

Thermoelectric generators might not be headline-grabbing tech, but their silent reliability makes them quietly revolutionary. We’ve seen how the Seebeck effect — the foundation of Seebeck power generation — allows these systems to convert heat directly into electricity without moving parts or emissions.

From powering NASA missions to recovering energy in industrial settings, thermoelectric power generators prove their value in the real world. Despite challenges like low efficiency and high material costs, breakthroughs in thermoelectric materials and nanotechnology are quickly changing the game.

As we transition toward cleaner, decentralized energy, the role of the thermoelectric effect is only growing. Whether it’s wearable devices, automotive enhancements, or deep-space exploration, TEGs offer a dependable solution where other methods fall short.

In a world full of wasted heat, thermoelectric modules offer a smart, sustainable way to turn loss into power — and that’s an innovation worth watching.

FAQs

What is the thermoelectric generator?

A thermoelectric generator (TEG) is a device that converts heat directly into electricity using the Seebeck effect. It requires no moving parts, making it highly reliable and silent in operation. When there’s a temperature difference across its thermoelectric materials, it generates an electrical current.

How much electricity can a thermoelectric generator produce?

The power output of a thermoelectric generator depends on the temperature difference and the type of thermoelectric materials used. Small TEGs might produce milliwatts (ideal for sensors or wearable devices), while larger systems in industrial settings can generate several hundred watts. However, their overall efficiency typically ranges from 5–8%.

What is the thermoelectric principle?

The thermoelectric principle is based on the Seebeck effect, where a temperature difference across two different conductors or semiconductors creates a voltage. This principle is at the heart of Seebeck power generation, allowing for the direct conversion of thermal energy into electrical energy.

What are TEGs used for?

Thermoelectric power generators are used in a wide range of applications, including powering deep-space missions, recovering waste heat in factories, improving fuel efficiency in cars, and even powering small electronic devices like sensors or wearables. They’re especially valuable in environments where reliability, silence, and maintenance-free operation are critical.