Contents

Imagine trying to start a race car in fifth gear — it’s going to be rough, noisy, and might just damage the engine. That’s exactly what happens when you start a large electric motor directly at full voltage. This is where electric motor starters come into play. They’re like the clutch and gears of your motor’s startup process, controlling the initial inrush of electricity and making sure things start smoothly.

Among the various reduced voltage starter methods available, the Star Delta Starter is hands-down one of the most popular and practical options, especially for industrial setups. Why? It’s cost-effective, relatively simple to implement, and significantly reduces the starting current — which is the massive surge of electricity motors usually draw during startup.

The Star Delta Starter is particularly common in systems using a three-phase induction motor. These motors are workhorses in manufacturing, HVAC systems, and heavy machinery. But starting them without precautions can cause serious voltage drops and wear out electrical components. That’s why the Star Delta Starter is so widely adopted — it helps reduce stress on the motor and the power system during motor starting, extending equipment lifespan and enhancing efficiency.

What is a Star Delta Starter?

A Star Delta Starter is a type of reduced voltage starter used for starting a three-phase induction motor by initially connecting the motor windings in a star configuration, and then shifting to a delta configuration once the motor reaches a certain speed. This method is specifically designed to reduce the high starting current that motors typically draw at startup.

When a motor is started directly on line (DOL), it draws a large inrush of current — often 6 to 8 times its full load current. This sudden surge can lead to voltage drops in the system and stress on electrical components. To mitigate this, engineers use reduced voltage starter systems like the Star Delta Starter. The purpose is simple: reduce the mechanical and electrical stress during motor starting, and improve the overall longevity and efficiency of the motor and connected systems.

Understanding the “star” and “delta” terminology is crucial. In the star connection (also called “wye”), the motor windings are connected in such a way that the voltage across each winding is reduced to 1/√3 (about 58%) of the line voltage. This results in a reduction of the current by about the same ratio. Once the motor reaches approximately 70–80% of its rated speed, the connection switches to delta, where the windings receive the full line voltage, allowing the motor to run at its full rated power.

This automatic transition is what makes the Star Delta Starter both efficient and cost-effective. It’s widely used in industries where large three-phase induction motors need to be started with care, such as compressors, fans, and pumps.

Working Principle Explained Simply

The beauty of a Star Delta Starter lies in its simplicity and effectiveness. It starts the three-phase induction motor in three key steps: star mode, transition, and delta mode. Let me walk you through how it works in real-world terms, without getting too technical.

Step 1: Star Mode

When the motor starts, its windings are connected in a star configuration. In this setup, each phase receives only 1/√3 (around 58%) of the line voltage. As a result, the motor draws significantly less starting current — usually about one-third compared to starting directly with full voltage.

Think of it like taking off gently instead of stomping on the gas pedal. This approach prevents voltage drops in the supply line and reduces mechanical stress on the motor’s internal components during motor starting.

Step 2: Transition

After a few seconds (typically 5 to 10), once the motor has built up speed and the current has stabilized, a timer or controller initiates the switch from star to delta. This process is known as the transition phase.

During this brief moment, all three contactors are open to prevent short-circuiting. Some systems experience a slight jerk or pause here, but high-quality starters manage this switch seamlessly.

Step 3: Delta Mode

Now the windings are reconnected in the delta configuration. In this mode, each winding gets the full line voltage, allowing the motor to operate at its rated power and speed. This is where the motor does its heavy lifting — whether it’s driving a conveyor belt, powering a compressor, or spinning up a fan.

Why This Method Reduces Starting Current

Starting directly in delta mode causes a huge current surge that can damage electrical equipment and trip protection devices. By starting in star, we effectively reduce the voltage (and hence the current) applied to each winding during startup.

This method is especially beneficial for systems that can’t tolerate high inrush currents. It makes the Star Delta Starter a preferred choice for motors larger than 5HP where soft starting is a necessity, not just a convenience.

Simple, smart, and efficient — that’s how the Star Delta Starter gets the job done without shocking your electrical system.

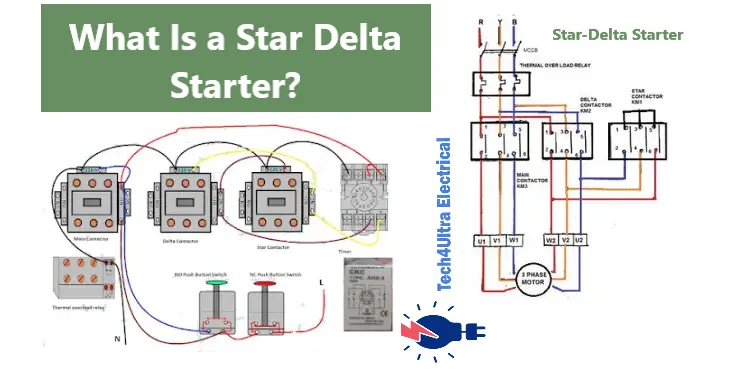

Star Delta Starter Circuit Diagrams

To truly understand how a Star Delta Starter functions, you need to see what’s happening under the hood — and that means looking at the circuit diagrams. These diagrams are typically divided into two parts: the power circuit and the control circuit. Each plays a vital role in ensuring a smooth motor starting process for any three-phase induction motor.

Power Circuit

The power circuit is responsible for handling the high current flowing into the motor. It includes three main contactors — Main (KM1), Star (KM2), and Delta (KM3) — as well as thermal overload protection and the motor windings themselves.

In the diagram:

- KM1 connects the power supply to the motor.

- KM2 links the motor windings in the star configuration.

- KM3 switches the windings to delta after startup.

At startup, KM1 and KM2 close together, enabling the motor to run in star mode and draw reduced starting current. After a preset time delay, KM2 opens and KM3 closes — shifting the motor to delta mode for full-speed operation.

Control Circuit

The control circuit manages how and when the contactors operate. It’s the brain of the system, ensuring safe and timed switching. The main elements here are:

- A start push button (usually marked as “ON”)

- A stop push button (“OFF”)

- A timer relay

- Overload relay contacts

When the start button is pressed, KM1 and KM2 energize simultaneously — triggering star mode. The timer starts counting. After the timer’s set delay (let’s say 10 seconds), it deactivates KM2 and activates KM3, completing the transition to delta mode.

If an overload condition is detected, the overload relay opens the control circuit and cuts off power to all contactors — preventing motor damage.

Stage-by-Stage Explanation

- Stage 1 – Star Mode: KM1 and KM2 closed, motor windings in star, low voltage, reduced current.

- Stage 2 – Transition: Timer activates, KM2 opens, brief neutral state (no current).

- Stage 3 – Delta Mode: KM3 closes, full voltage to motor windings, motor runs at full power.

These diagrams provide a complete picture of how the Star Delta Starter simplifies motor starting and protects against dangerous current surges. Whether you’re an engineer or a curious learner, studying both the power and control circuits gives you essential insights into this classic reduced voltage starter method.

Key Components of a Star Delta Starter

Every Star Delta Starter system is made up of a few essential components that work together like gears in a well-oiled machine. These parts aren’t just there for show — each one plays a crucial role in reducing starting current and ensuring smooth motor starting for a three-phase induction motor.

Contactor

There are usually three contactors in a Star Delta Starter: the main contactor (KM1), the star contactor (KM2), and the delta contactor (KM3).

- KM1 (Main Contactor): Connects the motor to the power supply.

- KM2 (Star Contactor): Links the motor windings in star configuration for reduced voltage at startup.

- KM3 (Delta Contactor): Switches the windings to delta configuration for full voltage once the motor reaches speed.

Without these contactors, there would be no way to switch between star and delta modes — which is the whole point of this reduced voltage starter setup.

Timer

The timer is the decision-maker. Once the start button is pressed, the timer starts counting down. Its job is to trigger the switch from star to delta mode at the right moment — usually between 5 to 15 seconds after startup, depending on the motor size.

A well-calibrated timer ensures that the motor doesn’t stay in star mode too long (which could delay full-speed operation) or switch too early (which could defeat the purpose of current reduction).

Overload Relay

The overload relay is your safety net. It monitors the current going into the motor and disconnects the power if it detects an overload condition — protecting the motor from damage.

In most designs, it sits after the main contactor and cuts off the entire control circuit if it trips. Think of it as the motor’s emergency brake.

Together, these components form the control backbone of a Star Delta Starter, making it reliable, safe, and efficient for managing the startup of industrial three-phase induction motors.

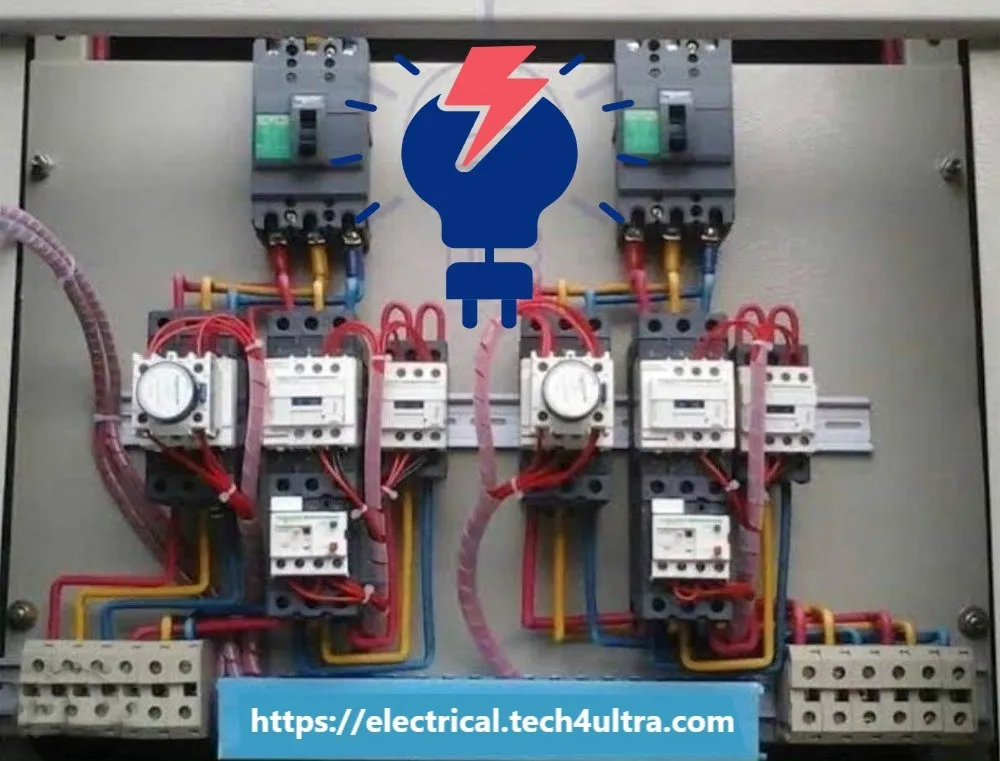

Construction and Internal Design

The internal build of a Star Delta Starter isn’t just about wires and boxes — it’s a carefully planned setup that ensures safe and efficient motor starting. Whether it’s installed inside a metal panel or a plastic enclosure, the design aims to balance accessibility, durability, and functionality.

Physically, the starter is built within a control panel that houses all the key components: the three contactors (KM1, KM2, KM3), the timer, overload relay, terminal blocks, and auxiliary relays. High-quality versions may also include fuses, push buttons, and indicator lights for added control and monitoring.

The layout follows a structured flow:

- Top Section: Typically reserved for the incoming power terminals and fuses.

- Middle Section: Contains the main, star, and delta contactors, arranged side by side.

- Lower Section: Hosts the overload relay and outgoing terminals to the three-phase induction motor.

The reduced voltage starter panel often includes labeling on all terminals and a wiring diagram on the inner door for quick reference during maintenance or troubleshooting.

Note: For a visual reference, here’s a simplified layout of a typical panel:

Every part is placed for logical flow — power comes in, passes through protection and control stages, then out to the motor. It’s clean, efficient, and engineered to handle the high inrush current without chaos.

Advantages and Disadvantages

While the Star Delta Starter is a favorite for many industrial applications, it’s not a one-size-fits-all solution. Let’s break down when this reduced voltage starter shines — and when it might fall short.

Advantages

- Reduced Starting Current: Cuts the inrush current to roughly one-third compared to direct-on-line starting, protecting the three-phase induction motor and power network.

- Lower Mechanical Stress: Smoothens startup, extending motor and equipment life.

- Cost-Effective: Cheaper than other soft starting methods like VFDs or autotransformer starters.

- Simple Maintenance: Uses basic, readily available components like contactors and timers.

Disadvantages

- Not Suitable for High Load Start: Doesn’t work well if the motor needs to start under heavy load — torque is lower in star mode.

- Complex Wiring: Involves more components and interlocks than direct starters.

- Mechanical Jerk: The transition from star to delta can cause a brief torque dip or voltage spike.

When It’s Ideal

Use a Star Delta Starter when you’re working with medium to large three-phase induction motors that start with no load or light load — like pumps, fans, or compressors.

When Not Recommended

If your motor starts under full load or needs precise control over speed and torque, consider alternatives like soft starters or VFDs. In these cases, the Star Delta Starter might actually do more harm than good.

Applications and Use Cases

The Star Delta Starter isn’t just a theory in textbooks — it’s used every day in industries that rely on large motors. Its role in reducing starting current makes it essential wherever three-phase induction motors are powering heavy-duty machines.

Industries That Rely on Star Delta Starters

- Manufacturing: Used in conveyor belts, presses, and mixers where smooth motor starting prevents mechanical wear and tear.

- Water Treatment Plants: Powers pumps and agitators with reduced electrical load during startup.

- HVAC Systems: Essential for running chillers, compressors, and fans without overloading the power system.

- Mining and Quarrying: Operates crushers, conveyors, and elevators, especially in remote areas with limited electrical capacity.

- Agriculture: Starts irrigation pumps and grain processing equipment smoothly and reliably.

Real-World Examples

Let’s say you’re running a factory that uses a 15kW blower fan. Starting it directly would spike your current draw and could cause nuisance tripping. But with a Star Delta Starter, the same fan starts smoothly, drawing less current and causing less stress on your power infrastructure.

Or imagine an industrial water pump in a bottling plant. It cycles frequently and can’t afford repeated power surges. Installing a reduced voltage starter like the star delta system keeps the operation stable and protects the pump motor.

These aren’t just hypothetical scenarios — they’re the daily reality for engineers in the field. Whenever a motor doesn’t need to start under full load, the Star Delta Starter is often the go-to solution.

Star Delta Starter vs. Other Starters

If you’re trying to choose the right starter for your motor, it’s crucial to compare the Star Delta Starter with other common methods like DOL (Direct-On-Line), soft starters, and VFDs (Variable Frequency Drives). Each one has its own benefits and limitations — and the right choice often depends on your application and budget.

Comparison at a Glance

| Starter Type | Starting Current | Torque Control | Cost | Use Case |

|---|---|---|---|---|

| Star Delta Starter | ~33% of full load | Limited during star mode | Low | Fans, pumps, light load machines |

| DOL Starter | 600–800% of full load | High (no control) | Very low | Small motors, under 5HP |

| Soft Starter | Adjustable | Good | Medium | Compressors, conveyors, HVAC |

| VFD (Variable Frequency Drive) | Precise control | Excellent | High | Applications needing speed/torque control |

Which One Should You Choose?

If your priority is low cost and simple motor starting for a three-phase induction motor that doesn’t start under load, the Star Delta Starter is a smart choice. It’s one of the most affordable reduced voltage starter options out there.

However, if you need fine control over torque or speed, or you’re starting motors with heavy loads, a soft starter or VFD might be worth the extra investment.

Common Problems and Troubleshooting

Even though the Star Delta Starter is known for its simplicity and reliability, it’s not immune to occasional hiccups. Understanding the most frequent operational problems — and how to fix them — can save you time, money, and motor downtime.

1. Motor Doesn’t Start

Diagnosis: Check if the main contactor (KM1) is engaging. If not, inspect the control voltage supply, start push button, or faulty coil.

Solution: Replace faulty contactor or ensure the control circuit is powered correctly.

2. Stuck in Star Mode

Diagnosis: The timer may not be functioning or is not properly wired, so it doesn’t trigger the delta contactor (KM3).

Solution: Test or replace the timer. Make sure transition wiring is secure.

3. Jerky Transition to Delta

Diagnosis: If the transition causes mechanical jerk or audible noise, it could be due to incorrect timing or simultaneous contactor engagement.

Solution: Adjust timer delay and verify mechanical interlock between KM2 and KM3 to avoid short circuits.

4. Overload Relay Tripping Frequently

Diagnosis: The motor might be under excessive load or the relay setting is too low.

Solution: Inspect the motor load and increase the relay setting within safe limits. If the problem persists, check for motor bearing or alignment issues.

5. Contactor Buzzing or Heating

Diagnosis: Loose wiring or faulty coil could be the cause.

Solution: Tighten all terminals, clean contact surfaces, or replace the contactor coil if necessary.

These issues are common in both new and aging systems. With a basic understanding of how the Star Delta Starter works, most of them can be diagnosed and fixed without calling in high-cost technical support. Always ensure the system is powered down before attempting any inspection or repair.

Simulation and Practical Implementation

Before physically wiring a Star Delta Starter in the field, many engineers and students prefer testing their designs in a virtual environment. Simulation tools not only save time and cost, but also help prevent common mistakes in motor starting setups involving three-phase induction motors.

Popular Simulation Tools

- MATLAB/Simulink: A powerful platform used for electrical and control system simulations. You can build a full reduced voltage starter circuit, including contactors, timers, and motor models, and analyze the current, voltage, and torque during startup.

- Proteus: Often used in educational settings. While its motor simulation capability is basic, it’s useful for control circuit logic and relay behavior.

- Multisim: Great for visualizing electrical behavior, especially in the control circuit of a Star Delta Starter.

How to Test Circuits Virtually

- Create the power and control circuit: Use the simulation software’s component library to add contactors, push buttons, timers, and the motor.

- Configure parameters: Set realistic voltage levels, delay times for the timer, and overload relay settings.

- Run the simulation: Observe the transition from star to delta and monitor current draw. Adjust timings to reduce startup jerk or prevent tripping.

- Analyze results: Use built-in tools to graph voltage, current, and torque to verify correct behavior.

Simulation allows you to visualize the effect of improper settings — like short delays or incorrect contactor sequencing — without risking real-world damage. Once verified, your design can be confidently transferred into a physical panel for real motor starting applications.

Conclusion

In today’s world of industrial automation and energy-conscious operations, the Star Delta Starter remains a reliable, budget-friendly choice for managing motor starting in three-phase induction motors. It may not offer the finesse of a VFD or the convenience of a soft starter, but its ability to drastically reduce starting current — without a high price tag — makes it a top pick for countless applications.

We’ve explored its construction, working principle, circuit diagrams, key components, and where it fits best. Whether you’re a student, a field technician, or a design engineer, understanding how this reduced voltage starter works can help you build safer, more efficient motor control systems.

If your next project involves motors over 5HP with no load at startup, don’t overlook the practicality of the Star Delta Starter. It’s simple, effective, and has stood the test of time.

Got a project coming up? Try simulating your circuit first, then bring it to life in the panel — it’s a learning experience you’ll thank yourself for!

FAQs

What is the star delta starter?

It’s a type of reduced voltage starter used to limit the starting current of a three-phase induction motor by starting in star mode and switching to delta once the motor reaches speed.

How does a star starter work?

A Star Delta Starter begins by connecting the motor windings in a star configuration to reduce the starting current. After the motor gains speed, it switches to a delta configuration to run at full voltage and power. This method minimizes the electrical and mechanical stress on the three-phase induction motor.

What is the advantage of star delta starter over DOL starter?

The main advantage is reduced starting current. While a DOL starter applies full voltage instantly — often leading to high inrush current — a Star Delta Starter limits the initial current to about one-third, making it safer for both the motor and the electrical system.

What is star delta starter used in ship?

On ships, the Star Delta Starter is commonly used for starting large auxiliary motors like seawater pumps, ballast pumps, or ventilation fans. It helps manage limited onboard power resources by reducing motor starting surges that could affect other sensitive equipment on the same electrical system.

Why is Star Delta used instead of Direct-On-Line (DOL)?

Because DOL causes high inrush current, which can damage electrical components. Star Delta limits this surge and makes motor starting smoother.

When should I not use a Star Delta Starter?

If the motor starts under full load or needs torque control from the beginning, it’s better to use a soft starter or VFD.

What size motors are ideal for Star Delta?

Motors from 5HP up to around 100HP are typical candidates, especially when started under light or no load.

Can I simulate a Star Delta Starter?

Yes! Tools like MATLAB, Proteus, and Multisim allow you to build and test virtual circuits before real-world implementation.

How long should the timer be set?

Usually between 5 to 15 seconds, depending on motor size and load conditions. It needs fine-tuning for best performance.

1 thought on “Eddy Currents Explained: Theory, Applications, and Real-World Innovations”