Contents

Here’s a fact that might surprise you: over 80% of faults in high-voltage power networks are caused by issues with switchgear or circuit breakers. Just one small component can bring an entire system to a halt. In this article on the Tech4Ultra Electrical website, you’ll get a clear, practical understanding of high voltage switchgear, high-voltage circuit breakers, and equipment rated for voltage above 36 kV. Whether you’re an engineer, technician, or planner, this guide will help you choose the right gear to reduce risk, enhance safety, and ensure grid stability.

What is High Voltage Switchgear?

If you’ve ever walked past a substation and wondered what all those metal boxes and buzzing sounds are, you’re looking at the nerve center of electrical distribution — and high voltage switchgear plays a starring role. In simple terms, it’s the equipment used to control, protect, and isolate electrical circuits operating at voltage above 36 kV.

Why does this matter? Imagine trying to maintain or repair a live 132 kV line without isolating it first. Dangerous, right? That’s where switchgear steps in — it ensures safety by allowing engineers to disconnect parts of the system, reroute power, and protect the grid from overloads and faults.

High-voltage circuit breakers, an integral part of this switchgear, can interrupt massive fault currents in milliseconds, preventing disasters. These systems are found across a wide range of industries: from power generation plants and transmission networks to heavy industrial facilities and offshore platforms.

In essence, high voltage switchgear is not just a piece of equipment — it’s a silent guardian keeping large-scale electrical systems stable, safe, and functional. Without it, even the most advanced infrastructure would be one short circuit away from chaos.

Read Also: Low Voltage Switchgear: Types, Components, and Uses

Voltage Classifications and Operational Thresholds

In electrical engineering, understanding voltage classifications is critical for designing safe and efficient systems. Voltage levels are typically divided into three main categories: low, medium, and high. Low voltage usually refers to systems operating below 1 kV, medium voltage spans from 1 kV to 36 kV, while high voltage covers anything above 36 kV.

This is where high voltage switchgear becomes essential. Once a system operates beyond the 36 kV threshold, the insulation, protection, and switching mechanisms must be significantly more robust. Such switchgear is designed to handle high energy loads and withstand extreme electrical stress, playing a vital role in maintaining reliability and safety.

The choice between voltage classes isn’t just technical — it directly influences infrastructure design, safety protocols, and maintenance planning. For example, installing high-voltage circuit breakers in the wrong voltage range can lead to underperformance or catastrophic failure. That’s why accurate classification is a foundational step in any power system design.

Main Functions and Importance

When it comes to protecting the grid, high voltage switchgear isn’t just another component — it’s the first line of defense. One of its primary roles is fault isolation. When a fault occurs, such as a short circuit, the switchgear instantly isolates the affected section, preventing the issue from cascading across the entire system.

Another critical function is overcurrent and arc protection. In high-voltage environments, electrical arcs can be incredibly destructive and dangerous. High-voltage circuit breakers are engineered to detect abnormal currents and extinguish arcs in fractions of a second, safeguarding both equipment and personnel.

Then there’s load transfer reliability. During maintenance or outages, power often needs to be rerouted. Switchgear ensures this transition happens smoothly, without causing interruptions or voltage dips that could affect sensitive systems.

Finally, and perhaps most importantly, switchgear contributes to power system stability. By regulating how electricity flows, isolating faults, and balancing load distribution, it helps maintain a constant and reliable supply of energy. In networks operating at voltage above 36 kV, this stability is not optional — it’s essential for avoiding blackouts and equipment damage.

Simply put, without the smart functionality of high voltage switchgear, our modern electrical infrastructure would be vulnerable and unpredictable.

Types of High Voltage Switchgear

There isn’t a one-size-fits-all solution when it comes to high voltage switchgear. Depending on the application, environment, and cost constraints, different insulation technologies are used to ensure safety and performance in systems operating at voltage above 36 kV.

Air Insulated Switchgear (AIS)

AIS is the most traditional type, using ambient air as the insulation medium. It’s cost-effective and easy to maintain but requires more space, making it ideal for rural or outdoor installations.

Gas Insulated Switchgear (GIS)

GIS uses sulfur hexafluoride (SF6) gas, which offers excellent dielectric properties in compact enclosures. It’s commonly used in urban substations where space is limited. However, SF6 is a potent greenhouse gas, which poses environmental concerns.

Oil Insulated Switchgear (OIS)

OIS systems use oil as both an insulator and arc-quenching medium. They are reliable and proven but come with higher maintenance demands due to potential oil leaks and fire hazards.

Vacuum Insulated Switchgear

This type employs vacuum interrupters to handle arc extinction. It’s clean, safe, and requires minimal maintenance. Vacuum technology is growing in popularity for medium-to-high voltage systems, especially in industrial applications.

Comparison Table

| Type | Pros | Cons | Typical Use Cases |

|---|---|---|---|

| Air Insulated (AIS) | Low cost, easy maintenance | Bulky, not ideal for dense areas | Rural substations, open switchyards |

| Gas Insulated (GIS) | Compact, high reliability | High cost, SF6 environmental impact | Urban substations, offshore platforms |

| Oil Insulated (OIS) | Good performance, proven technology | Maintenance-heavy, fire risk | Older substations, backup systems |

| Vacuum Insulated | Eco-friendly, low maintenance | Higher initial cost for HV | Industrial facilities, renewable energy plants |

Choosing the right high-voltage circuit breaker and switchgear type depends on balancing performance, safety, space, and environmental impact — and getting this choice right is crucial for system efficiency and longevity.

Watch Also: Sources of Electrical Energy: Types and How They Work

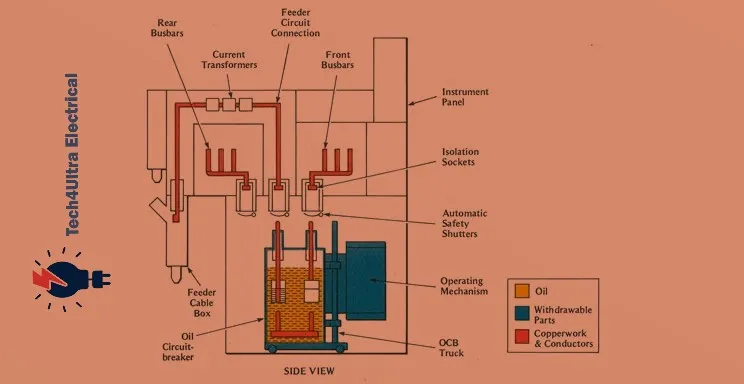

Key Components of High Voltage Switchgear

Every high voltage switchgear assembly is like a well-orchestrated system of components working together to protect, control, and manage electricity at voltage above 36 kV. Understanding these components helps engineers maintain reliability and make informed design decisions.

Circuit Breakers

The heart of the switchgear. High-voltage circuit breakers detect and interrupt fault currents. Whether it’s SF6, vacuum, or oil-based, their primary job is arc extinction and quick fault clearing.

Disconnect Switches

These are mechanical devices used to isolate equipment for maintenance. They operate under no-load conditions and ensure visible separation from live parts.

Fuses

Although not common in ultra-high voltage systems, fuses are still used for localized protection, especially in auxiliary circuits within the switchgear panel.

Instrument Transformers

These include Current Transformers (CTs) and Voltage Transformers (VTs). They step down high voltages and currents to measurable levels for metering and protection devices.

Surge Arresters

Protect the system against transient overvoltages like lightning strikes or switching surges. They absorb and safely redirect the energy away from sensitive components.

Earthing Switches

Used to ground isolated sections for safe maintenance. They’re crucial in ensuring no stray voltages are present when technicians are at work.

Control Panels

The brain of the operation. These panels house protection relays, metering devices, communication modules, and manual control interfaces.

Load Break Switches

Unlike disconnect switches, these can operate under load. They’re used to switch electrical circuits during normal operation without causing interruption.

Typical Component Layout Diagram

Each of these components plays a critical role in the safety and effectiveness of a high voltage switchgear system. From fault detection to routine maintenance, having the right combination ensures smooth operation under the toughest conditions.

Safety Mechanisms and Fail-Safe Features

Operating at voltage above 36 kV means one thing — there’s zero room for error. That’s why high voltage switchgear is built with advanced safety mechanisms designed to prevent catastrophic failure and protect both personnel and equipment.

Overcurrent and Arc Flash Protection

When excessive current flows through a system, high-voltage circuit breakers spring into action. They detect fault conditions and cut off power in milliseconds to prevent arc flashes, which can release deadly energy levels.

Grounding and Interlocking Systems

Earthing switches and mechanical/electrical interlocks ensure no section of the switchgear can be accessed unless it’s safely de-energized. These features are mandatory in modern systems and are designed to eliminate human error during maintenance.

Environmental Protections

Enclosures are engineered to resist extreme heat, moisture, dust, and chemical exposure. In oil and gas insulated systems, detectors monitor for SF6 gas leakage or oil level changes, alerting operators before things escalate. Fire suppression mechanisms are also integrated, especially in indoor setups.

Vacuum Interrupters and SF6 Insulation

Vacuum interrupters are widely favored for arc quenching due to their reliability and zero-emission operation. In gas insulated switchgear, SF6 offers unmatched dielectric strength but must be handled with care due to its environmental impact. Proper containment, recycling systems, and leakage monitors are standard fail-safe features.

Ultimately, every element of high voltage switchgear is built around the core principle of safety — because in high-voltage networks, one failure can affect an entire region’s power supply.

Installation and Maintenance Considerations

Installing and maintaining high voltage switchgear isn’t just about plugging in hardware — it’s about adapting to real-world conditions and ensuring long-term performance. Whether it’s placed indoors or outdoors, the site environment plays a massive role in setup and reliability.

Site Conditions: Indoor vs Outdoor

Indoor installations are easier to control in terms of temperature, humidity, and contamination, making them ideal for gas insulated switchgear (GIS). Outdoor switchgear, often air-insulated, requires weatherproof enclosures and UV-resistant coatings to withstand heat, rain, and dust exposure.

Cooling and Ventilation

At voltage above 36 kV, components generate significant heat. Ventilation systems — whether passive louvers or forced cooling fans — are crucial to avoid overheating and ensure safe operation.

Periodic Testing and Insulation Checks

Routine maintenance includes insulation resistance testing, partial discharge measurements, and thermal imaging. These tests detect aging or damaged insulation before failure occurs, especially in high-voltage circuit breakers where breakdowns can be catastrophic.

Common Faults and Diagnostics

Frequent issues include contact wear, insulation degradation, moisture ingress, and control panel failures. Diagnostic tools like circuit breaker analyzers, SF6 gas density monitors, and infrared scanners help technicians pinpoint problems early and extend equipment lifespan.

Proactive maintenance of high voltage switchgear isn’t optional — it’s the difference between uninterrupted power and expensive downtime.

Applications in Power Systems

Wherever electricity is generated, transferred, or distributed at voltage above 36 kV, you’ll find high voltage switchgear quietly doing its job. It’s the critical link between generation and end-users, designed to control and protect high-voltage circuits under all operating conditions.

Transmission and Distribution

In transmission networks, high-voltage circuit breakers and switchgear isolate faults and allow flexible routing of electricity across long distances. Without them, a single fault could cascade into a regional blackout. In distribution systems, switchgear helps step down voltage and safely deliver power to neighborhoods and commercial zones.

Power Plants and Substations

Switchgear forms the protective backbone of generation stations. Whether in a hydroelectric dam or nuclear facility, it controls outgoing feeds and prevents overloads. In substations, it integrates with transformers to safely manage voltage transitions, fault isolation, and load balancing between multiple feeders.

Industrial Facilities

Heavy industries like mining, oil and gas, and manufacturing rely on high voltage switchgear to maintain a steady energy supply for critical operations. Downtime here isn’t just inconvenient — it’s financially devastating.

Simply put, without switchgear, large-scale electrical systems couldn’t function safely or reliably. It’s the unsung hero of every modern power network.

Environmental and Regulatory Aspects

As powerful as high voltage switchgear is, it comes with environmental responsibilities — especially when operating at voltage above 36 kV. A major concern is the use of SF6 gas, commonly found in gas insulated switchgear (GIS). While SF6 is an excellent insulator, it’s also a potent greenhouse gas. That’s why strict containment, recycling systems, and leak monitoring are now standard in compliant installations.

To address this, manufacturers are exploring eco-friendly alternatives like fluoronitrile-based mixtures or vacuum technologies, especially in medium and high-voltage systems.

From a regulatory standpoint, compliance with global standards like IEC 62271 and IEEE C37 ensures that high-voltage circuit breakers and related equipment meet safety, performance, and environmental benchmarks. These standards dictate everything from insulation testing to arc flash protection levels.

Additionally, oil insulated switchgear must include fire suppression and containment systems to prevent hazards from oil leaks and combustion. Enclosures often feature bund walls or catchment basins to control spills and avoid soil or water contamination.

In today’s power landscape, balancing performance with environmental and regulatory compliance is no longer optional — it’s a core part of responsible switchgear design.

Watch Also: What is a Megger? Working Principle and Applications

Future Trends in High Voltage Switchgear

The future of high voltage switchgear is all about smarter, cleaner, and more connected systems — especially as global grids evolve. With the rise of renewable energy and decentralized generation, traditional infrastructure is being reshaped to support dynamic, data-driven networks.

Smart Grid Integration

Modern switchgear is no longer passive. It’s becoming intelligent, feeding real-time data into control systems to enhance grid responsiveness. These systems help operators detect issues, predict failures, and automatically reroute power to maintain stability at voltage above 36 kV.

Digital Switchgear

High-voltage circuit breakers are now equipped with sensors and digital relays, reducing the need for manual intervention. This not only boosts safety but also enables remote diagnostics and predictive maintenance — key components in Industry 4.0 strategies.

Eco-Friendly Insulation

Environmental pressure is pushing manufacturers to replace SF6 with low-emission alternatives. Vacuum interrupters and fluorinated gas mixtures are gaining traction, especially in compact GIS units. The result? Lower carbon footprints without compromising performance.

Tomorrow’s switchgear is smarter, greener, and fully integrated into a digital energy ecosystem — and it’s already changing how power systems are built and managed.

Conclusion

From managing voltage above 36 kV to protecting critical infrastructure, high voltage switchgear plays an indispensable role in modern power systems. Whether it’s through high-voltage circuit breakers, smart diagnostics, or advanced insulation methods, these systems ensure safe, stable, and efficient energy flow.

We’ve explored its components, types, safety mechanisms, and future trends — and one thing is clear: reliability begins with proper design and maintenance. As each system has its own operational and environmental demands, there’s no substitute for a tailored approach.

For engineers, planners, and operators, investing in high-quality switchgear isn’t just about compliance — it’s about building resilient networks that can power the future, fault-free.

FAQs

What is high voltage switchgear?

High voltage switchgear refers to electrical equipment used to control, protect, and isolate power systems operating at voltage above 36 kV. It includes components like high-voltage circuit breakers, disconnect switches, and protective relays designed to handle large power loads safely and reliably.

What are the three types of HV switchgear?

The main types of high voltage switchgear are:

- Air Insulated Switchgear (AIS) – uses air as the primary insulation medium; ideal for open environments.

- Gas Insulated Switchgear (GIS) – compact, sealed systems using SF6 gas; suited for space-limited or urban settings.

- Oil or Vacuum Insulated Switchgear – used in industrial setups; vacuum interrupters offer eco-friendly alternatives.

What is LV and HV switchgear?

LV switchgear (Low Voltage) handles voltages below 1 kV, commonly used in residential and small commercial buildings. HV switchgear (High Voltage) operates at voltages above 36 kV and is essential for large-scale power transmission and industrial networks.

What is HT and LT switchgear?

HT (High Tension) switchgear is another term for high voltage switchgear, generally referring to equipment rated above 11 kV. LT (Low Tension) switchgear refers to low voltage systems, typically below 1 kV, used in everyday applications like homes, offices, and light industries.

1 thought on “Electric Power System: Key Parts and How It Works”