Contents

Ever wondered why unexpected power outages still happen despite having modern protection systems in place? The truth is, many electrical failures stem from poor design or misselection of the switchgear protection system. The real issue? Understanding electrical switchgear and mastering the principles of power system protection isn’t as straightforward as it seems. In this article on the Tech4Ultra Electrical website, you’ll discover the essentials of designing robust protection systems, how to choose the right components, and how to ensure your electrical setup runs safely, efficiently, and without interruptions.

What is switchgear protection?

When I first walked into a live substation during my early training, I was overwhelmed by the number of cabinets, relays, and complex wiring. That’s when I truly grasped the role of switchgear protection. In simple terms, it’s the safety mechanism of the electrical world—responsible for isolating faults and ensuring smooth operation of the grid. Whether it’s a circuit breaker tripping during an overload or a fuse responding to a short circuit, electrical switchgear makes it all happen, often within milliseconds.

Importance in modern electrical systems

As electrical systems grow more interconnected and sensitive, the importance of reliable switchgear protection cannot be overstated. A single failure in a protection device can cascade into system-wide blackouts, damaging equipment and disrupting lives. I’ve seen industrial plants come to a standstill because of a failed relay. This is why power system protection isn’t just technical—it’s critical for operational continuity and safety.

Brief historical evolution of switchgear

Back in the early 20th century, switchgear was bulky, mechanical, and prone to arc flashes. Over time, with advancements in insulation, automation, and fault detection, electrical switchgear evolved into the sleek, intelligent systems we rely on today. The journey from knife switches to smart relays is proof of how far we’ve come in protecting our power infrastructure.

Read Also: High Voltage Switchgear: Types, Components, and Safety

Core Functions and Objectives of Protection Schemes

Safety

One of the first things I learned in the field: nothing matters more than safety. A well-designed switchgear protection scheme literally saves lives. I’ve witnessed what happens when protection systems fail—equipment explodes, arcs flash, and everything turns chaotic. Electrical switchgear is your first line of defense, protecting operators, maintenance crews, and even bystanders from dangerous faults and overcurrents.

Continuity of service

Downtime is expensive. In industrial settings, every second counts. Effective power system protection ensures that even when a fault occurs, only the affected part is isolated, allowing the rest of the system to keep running. I once helped configure a protection relay that isolated a fault within 0.04 seconds—production never even paused. That’s the real-world power of continuity planning.

Fault detection and isolation

You can’t fix what you can’t detect. Switchgear protection schemes use relays and sensors to detect abnormal conditions instantly. Whether it’s an earth fault, overload, or short circuit, the system reacts faster than a human ever could. Then, it isolates the problem area, limiting damage and simplifying repair. I’ve often relied on these systems to pinpoint issues without tearing the whole installation apart.

Impact on power system stability

It’s simple: instability leads to blackouts. Proper power system protection keeps the grid balanced, managing load flow and preventing cascading failures. In large-scale power networks, one misstep can ripple across cities. But with intelligent electrical switchgear, those ripples get absorbed before they grow into waves.

Watch Also: Motor Protection Guide: Types, Devices, Faults & NEC Selection Tips

Types of Switchgear and Where Protection Applies

Low-voltage, medium-voltage, and high-voltage switchgear

The first time I dealt with low-voltage switchgear was during a panel installation in a commercial building—simple stuff, yet critical for protecting lighting and small equipment. But things change quickly when you step into the world of medium-voltage and high-voltage switchgear. That’s where precision and timing become non-negotiable.

Low-voltage electrical switchgear typically handles up to 1,000V and is used in residential and small commercial setups. It includes circuit breakers, fuses, and contactors. Medium-voltage switchgear (1kV to 36kV) is the backbone of industrial power distribution. I remember commissioning a motor control center running on 11kV—those protection relays were our eyes and ears. For high-voltage switchgear (above 36kV), protection is a whole different game—used in power plants and transmission grids, where mistakes are costly and dangerous.

Indoor vs. outdoor applications

Another thing that caught me off guard early in my career: how location changes everything. Indoor switchgear is common in factories and commercial buildings. It’s protected from weather but demands strict ventilation and insulation. On the other hand, outdoor switchgear—used mainly in substations—faces heat, dust, and rain. That means weatherproof enclosures and extra care in grounding and surge protection. Each setup comes with its own challenges and protection considerations.

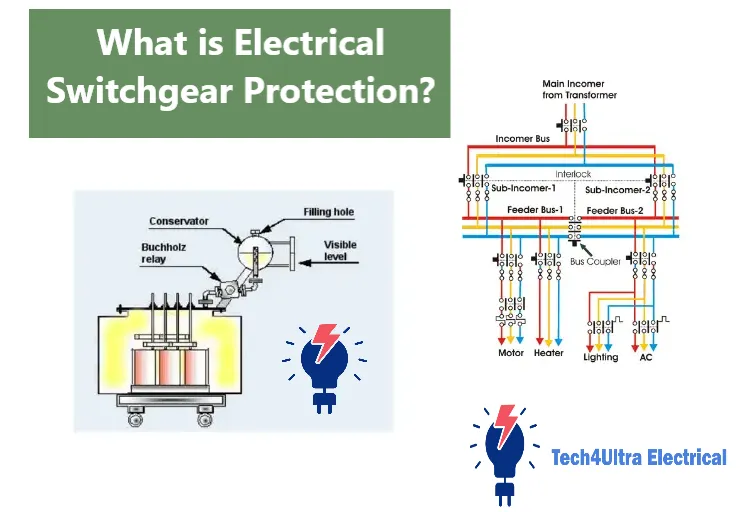

Use in substations, industries, utilities

I’ve seen switchgear protection applied across all sectors. In substations, it’s all about grid stability. In manufacturing, it ensures uptime and worker safety. And in utilities? It’s the silent guardian behind every flick of a light switch in your home. From transformers to feeders, power system protection is woven into every connection. Without it, you’re gambling with millions in equipment—and lives.

Watch Also: Low Voltage Switchgear: Types, Components, and Uses

Detailed Overview of Protection Devices

Circuit breakers: types, functions, and arc interruption

The first time I saw a circuit breaker interrupt a live fault, it felt like magic. But it’s pure engineering. At the core of any switchgear protection system, circuit breakers play the hero’s role—instantly opening a circuit to stop the fault current. They don’t just switch off power—they interrupt arcs that can reach thousands of degrees.

You’ve got types like air circuit breakers (ACBs), oil circuit breakers, SF₆ breakers, and vacuum circuit breakers, each tailored to specific voltages and applications. I remember replacing a failed SF₆ unit in a high-voltage yard; the cleanup and recharging were tedious but crucial. Each type comes with trade-offs in speed, reliability, and maintenance needs.

Protective relays: mechanical, static, numerical

Relays are the brains of the power system protection. I’ve worked with all three generations—mechanical, static, and numerical—and I’ll tell you, the evolution is fascinating. Mechanical relays, all moving parts and coils, were great in their time. Then came static relays—fewer moving parts but still analog. Today, it’s all about digital numerical relays.

The numerical ones? Game changers. They’re programmable, fast, and give detailed logs. I once used one to trace a persistent fault to a miswired CT—it saved us hours. These relays don’t just detect faults—they diagnose them.

Fuses, reclosers, vacuum interrupters

Don’t underestimate the old-school fuse. It’s still used in many low-cost or compact systems. Simple, fast, and reliable—but single-use. Reclosers, on the other hand, are like smart breakers. I once configured one for a rural feeder that faced constant tree branch faults. It would trip and then reclose after a second—most faults were cleared automatically, no need to roll a truck.

Vacuum interrupters are another gem, especially in medium-voltage electrical switchgear. They offer clean, low-maintenance interruption. No oil, no gas, just efficiency. I’ve replaced old oil breakers with vacuum types—they’re faster, safer, and quieter.

Role of instrument transformers

We can’t measure or control what we can’t sense. That’s where instrument transformers—CTs and PTs—come in. They scale down high voltage and current so protection devices can safely monitor them. I always double-check CT polarity during installs. One reversed CT can make a protection relay completely blind—and that’s how blackouts start.

Watch Also: What Is Clamping Voltage? How It Protects Your Devices

Modern Digital and Numerical Protection Relays

Features and advantages

When I first encountered digital relays, I was skeptical—too many settings, too much programming. But once I got the hang of it, I never wanted to go back. Modern numerical relays are not just upgrades; they’re a whole new world for switchgear protection. They combine speed, accuracy, and intelligence in one compact unit.

You get event logs, fault records, remote configuration, and even real-time monitoring. That means when a fault occurs, you don’t just know it happened—you know exactly when, where, and why. These features cut down troubleshooting time drastically. I once traced an earth fault to a corroded cable gland using just the relay’s event log. Total lifesaver.

Multi-function capabilities

Back in the day, each function needed a separate relay. Overcurrent? One device. Earth fault? Another one. Distance protection? Yet another. Now, a single numerical relay can handle all of those—and more. I’ve installed units that manage overcurrent, earth fault, frequency protection, voltage imbalance, and breaker failure—all in one box.

This consolidation means less panel space, lower installation costs, and easier maintenance. Plus, updates are just a firmware upload away. That’s a game-changer for both new systems and retrofit jobs.

Smart grid integration

Here’s where things get futuristic. These relays don’t just protect—they communicate. Using protocols like IEC 61850, they talk to SCADA systems, energy meters, and even other relays. In one of my utility projects, we had relays across different substations syncing with each other in real-time. That level of integration boosts the reliability of the entire power system protection framework.

With electrical switchgear moving toward digitization, these relays are the glue that holds everything together—fast, smart, and always alert.

Watch Also: Measurement of Resistance: A Complete Guide

How Protection Schemes Work: Principles & Logic

Current/voltage sensing

The foundation of every switchgear protection system is simple: sense a problem before it causes damage. But executing that idea? That’s where precision comes in. It starts with current and voltage transformers—CTs and PTs. These instrument transformers scale down massive voltages and currents into safe, measurable signals. I’ve installed dozens of CTs, and trust me—get the polarity wrong, and the whole power system protection logic goes sideways.

Whether it’s a high inrush current or a subtle voltage sag, these transformers feed data to relays that constantly monitor for abnormalities. They’re the eyes and ears of your electrical switchgear.

Relay logic and threshold detection

Once the measurements are in, relays do the thinking. Each relay is programmed with thresholds—maximum allowable current, undervoltage limits, differential margins. I’ve configured relays to detect overloads lasting just 0.2 seconds. The speed and accuracy still impress me.

The logic can be basic—trip if current exceeds 150% for 3 seconds—or complex, like differential protection that compares input and output current to detect internal faults. I’ve used both in substation setups, and when tuned correctly, they’re deadly accurate. False trips are rare if the logic is built right.

Tripping and coordination mechanisms

Detection is only half the job. The other half? Acting fast. When a fault is detected, the relay sends a trip signal to a circuit breaker, opening the circuit to stop the current flow instantly. But it’s not just about tripping—it’s about coordination.

In layered systems, protection must be selective. If a fault occurs at a motor, you don’t want the entire plant shutting down. That’s why we use time delays and backup settings. In one case, I tuned a breaker to trip at 0.1 seconds while its upstream partner waited 0.3 seconds. Fault handled—rest of the system kept running.

This balance of sensing, logic, and timing is what makes switchgear protection so powerful—and so essential.

Protective Zones and Relay Coordination Strategies

Definition and segmentation of protective zones

Early in my career, I struggled to understand how protection systems knew exactly where a fault occurred. The answer lies in protective zones. Each zone is a defined segment of the power system—like a transformer, a busbar, or a feeder—with dedicated switchgear protection. The beauty of this setup is in precision. If a fault hits a transformer, you don’t want the upstream line to open unless it absolutely has to.

We typically segment zones to match the physical layout of the system. In one substation upgrade I handled, we created individual zones for each outgoing feeder and the main busbar. This helped us pinpoint faults instantly and react with accuracy.

Primary and backup protection

Think of primary protection as your first responder. It’s the fastest, most precise setup—usually located closest to the equipment it protects. But things don’t always go as planned. Relays fail. CTs go open-circuit. That’s where backup protection comes in.

I’ve seen a case where a primary relay failed to detect a fault due to a wiring issue. Thankfully, the backup relay on the upstream breaker kicked in. Sure, it isolated a larger section than necessary, but it saved the entire system from damage. Power system protection isn’t just about being fast—it’s about being reliable under pressure.

Selectivity, dependability, and security explained

Every protection strategy must juggle three goals: selectivity, dependability, and security. Selectivity ensures only the faulty section is isolated. Dependability guarantees it’ll always trip when needed. And security prevents it from tripping when it shouldn’t.

Balancing these is both an art and a science. I once adjusted time delays on two relays to ensure the downstream one always tripped first. A millisecond too early or late could flip the whole logic. Electrical switchgear setups must be tuned carefully, especially in complex grids, where one wrong trip can ripple across the system.

Relay coordination isn’t glamorous, but it’s the backbone of a resilient network. If you get this part right, everything else becomes easier.

Common Protection Schemes with Diagrams

Overcurrent protection

The most basic—and one of the most used—switchgear protection methods is overcurrent protection. It’s often the first line of defense in electrical switchgear setups, especially for feeders and motors. I’ve used it extensively in factories, where current spikes are common during motor startups.

Flowchart:

[Current Sensed] → [Compare to Threshold] → [If Exceeds] → [Trip Signal Sent to Breaker]

Overcurrent protection works well in systems with clear fault current margins, but it needs time coordination to avoid false trips during normal inrush events.

Differential protection

This is the go-to method for transformers, busbars, and generators. It compares the current entering and leaving a zone—any mismatch signals a fault. I still remember the first time I tested a faulty CT wiring setup; the differential relay didn’t trip as it should. That day, I learned the importance of CT matching.

Diagram:

[CT1] ---\

>--- [Relay Logic] --- [Trip Breaker]

[CT2] ---/

It’s precise and fast, but only works if CTs are calibrated and correctly installed.

Distance protection

This one feels like magic—used mostly in high-voltage transmission lines. It calculates the impedance (Z = V/I) between the relay and the fault location. If the value falls below a set threshold, it means a fault is nearby. I’ve configured distance relays that segmented a 132kV line into multiple zones, giving fast trips for near faults and delayed trips for distant ones.

Flowchart:

[Voltage & Current Input] → [Impedance Calculation] → [Zone Matching] → [Trip Signal]

Perfect for long lines where fault current alone isn’t a reliable indicator.

Pilot protection

This one’s more advanced—used in transmission systems requiring end-to-end communication. Think of it as a relay talking to its twin at the other end of the line. If both detect the same fault simultaneously, the trip is instant. I’ve seen it used with fiber optic links between substations.

Diagram:

[Relay A] ⇄ [Pilot Channel] ⇄ [Relay B]

\ /

→ Both Detect Fault → Trip

This method ensures speed and selectivity, but requires robust comms infrastructure.

Each scheme has its strengths, and often, we layer them together for more reliable power system protection.

Real-World Applications and Case Studies

Examples from industrial, utility, and renewable energy sectors

Over the years, I’ve worked across multiple sectors, and the need for robust switchgear protection is universal. In an industrial setting, I managed a packaging plant with high-speed motors. One faulty contactor led to repeated motor trips. Installing a numerical relay with overcurrent and thermal protection solved the issue overnight—no more shutdowns, and maintenance costs dropped.

In the utility sector, I was part of a substation upgrade project for a rural grid. The existing electrical switchgear relied on basic mechanical relays. After a lightning strike damaged a feeder, we replaced them with digital units featuring pilot protection and remote diagnostics. The next storm came and went—zero downtime.

Renewable energy brings its own challenges. At a solar farm, we faced nuisance tripping due to inverter harmonics. The power system protection needed fine-tuning. After adjusting relay sensitivity and isolating each inverter string with local protection zones, the system stabilized and output returned to normal.

Issues faced and how protection mitigated failures

One of the most critical failures I witnessed was at a factory where a transformer shorted internally. No differential protection was in place. The upstream breaker tripped late, causing a fire. Afterward, we installed differential relays on all major transformers. Six months later, another fault occurred—this time, the relay isolated it in under 0.03 seconds. No fire. No damage.

Protection isn’t just about preventing outages—it’s about minimizing damage, saving lives, and preserving assets. Whether it’s load shedding during high demand or isolating a faulty cable, the role of switchgear protection is irreplaceable.

Watch Also: What is a Megger? Working Principle and Applications

Emerging Trends in Switchgear Protection

IoT-enabled devices

We’re not just protecting circuits anymore—we’re connecting them. The rise of IoT in switchgear protection has changed how we monitor and manage electrical systems. Devices now report temperature, humidity, load, and status in real-time to cloud-based platforms. I worked on an industrial plant where we installed IoT-enabled relays that alerted us via SMS if a breaker tripped. The shift from reactive to proactive management was immediate.

Predictive maintenance using AI

This is where things get exciting. AI algorithms now analyze historical data from electrical switchgear to predict failures before they happen. At a solar facility I supported, machine learning flagged an overheating breaker that looked fine in visual inspections. Days later, we found internal corrosion. AI didn’t just help—it prevented a costly shutdown. That’s the power of predictive power system protection.

Cybersecurity in relay networks

With everything getting connected, cybersecurity is no longer optional. Modern relays use Ethernet, Modbus, and IEC 61850 protocols—great for integration, risky for exposure. I’ve seen penetration tests where a single unsecured port exposed an entire protection network. Now, encrypted communication, role-based access, and firmware validation are part of our checklist.

As we move toward smarter, interconnected grids, the protection layer must evolve too—not just in function, but in foresight and defense.

Conclusion

Switchgear protection isn’t just a technical necessity—it’s the heart of electrical system reliability. From understanding the core types of electrical switchgear to the logic behind relay coordination, every layer plays a vital role in keeping systems safe, efficient, and operational.

We explored how power system protection ensures both safety and continuity across different sectors, and how evolving technologies like IoT, AI, and cybersecurity are reshaping the landscape. Real-world examples proved that good protection isn’t about luck—it’s about planning, precision, and constant learning.

Looking forward, the demands on protection systems will only grow. Grids are becoming smarter, loads more dynamic, and threats more complex. Future-ready protection means embracing digital tools, thinking ahead, and making safety a daily priority—not just a design checkbox.

If you take one thing from this: solid protection isn’t expensive—it’s priceless. One trip avoided, one fire prevented, one system restored in seconds can justify years of investment. And in this field, preparedness always pays off.

FAQs

What is the switchgear protection?

Switchgear protection refers to the system designed to detect and isolate electrical faults. It ensures the safety of equipment and personnel by disconnecting faulty components before they cause widespread damage or system instability.

What is the purpose of an electrical switchgear?

Electrical switchgear controls, protects, and isolates electrical equipment. Its main purpose is to ensure safe operation of power systems by allowing parts to be energized or de-energized as needed during maintenance or fault conditions.

What are the three types of switchgear?

The three main types of switchgear are:

- Low-voltage switchgear – used in residential and small commercial settings.

- Medium-voltage switchgear – common in industrial and distribution networks.

- High-voltage switchgear – used in transmission and large utility systems.

What is the principle of switchgear?

The principle behind switchgear is to detect abnormal conditions—like overcurrent or short circuits—and then safely interrupt the electrical flow using relays and breakers. This helps maintain system stability and protect both equipment and personnel.